FAHRION Collets

Precise, durable and significantly more efficient

In terms of quality, FAHRION collets already deliver performance in the standard range that other manufacturers reserve for expensive premium series.

Our precision collets, based on DIN ISO 15488 (ER/ESX) and DIN ISO 10897 (OZ), are manufactured with tolerance values that far exceed the requirements of the DIN standard.

FAHRION offers a wide variety of shapes and versions for different applications of collets per DIN ISO 15488 (ER/ESX).

Precise

Stable

Gentle

ER Collets Overview

All Collet Information at a Glance

elastomer sealing

(through collet)

not recommended

not recommended

not recommended

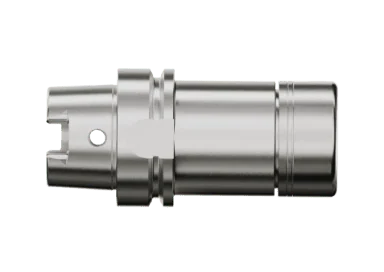

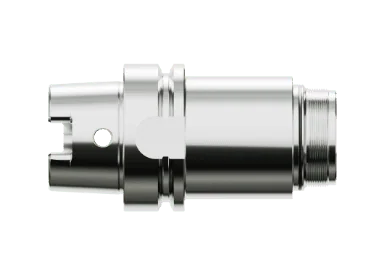

Full Performance Chuck - FPC

not recommended

not recommended

not recommended

not recommended

not recommended

not recommended

not recommended*

not recommended*

not recommended*

ER11

ER16

ER20

ER25

ER32

ER40

ER16

ER20

ER25

ER32

ER40

ER20

ER25

ER32

ER40

ER11

ER16

ER20

ER25

ER32

ER40

ER16

ER20

ER25

ER32

ER40

ER16

ER20

ER25

ER32

ER40

ER40

ER40

ER16

ER20

ER25

ER32

ER40

ER16

ER20

ER25

ER32

ER40

* Only DIN ISO 15488 compliant after removal of the blue ring.

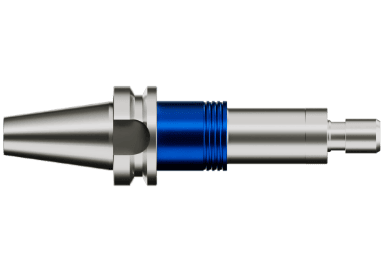

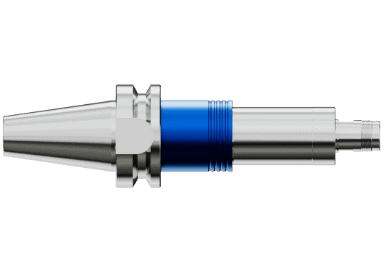

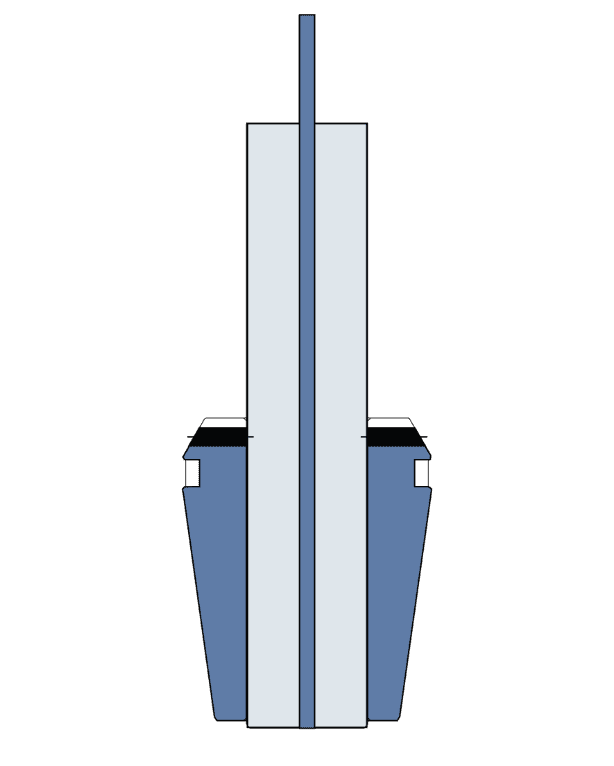

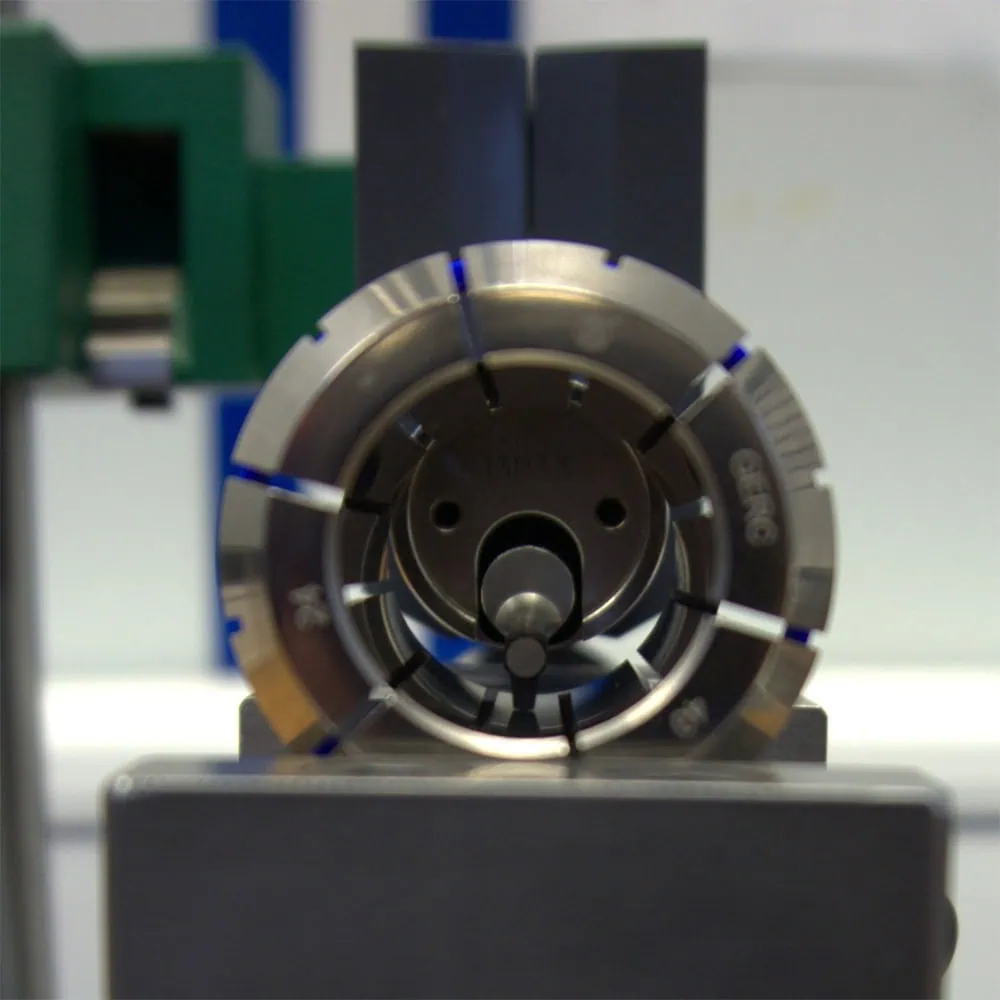

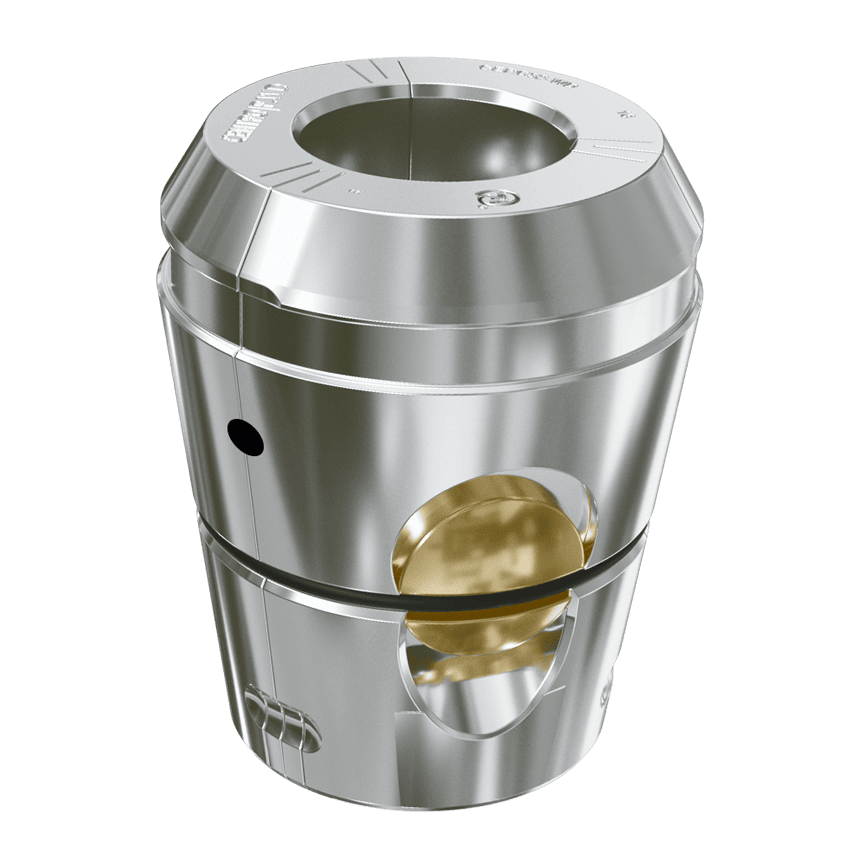

THE HIGH-PRECISION SYSTEM COLLET (2 µm)

High-performance clamping systems today are characterised by a concentricity of 3 µm. The FAHRION CENTRO|P clamping system, in combination with the 2 µm HP collet, achieves this 3 µm at 3x the overhang.

Thanks to these accuracy levels, the CENTRO|P collet clamping system competes with well-known technologies such as hydraulic expansion, thermal shrink and mechanical shrinking. Unlike these systems, CENTRO|P is composed of several components, making it much more flexible. For example, by simply changing the collet – the heart of our system – it can adapt to different tool diameters, coolant supplies, or machining tasks.

The blue ring is the globally recognised symbol of the 2 µm FAHRION high-precision collet.

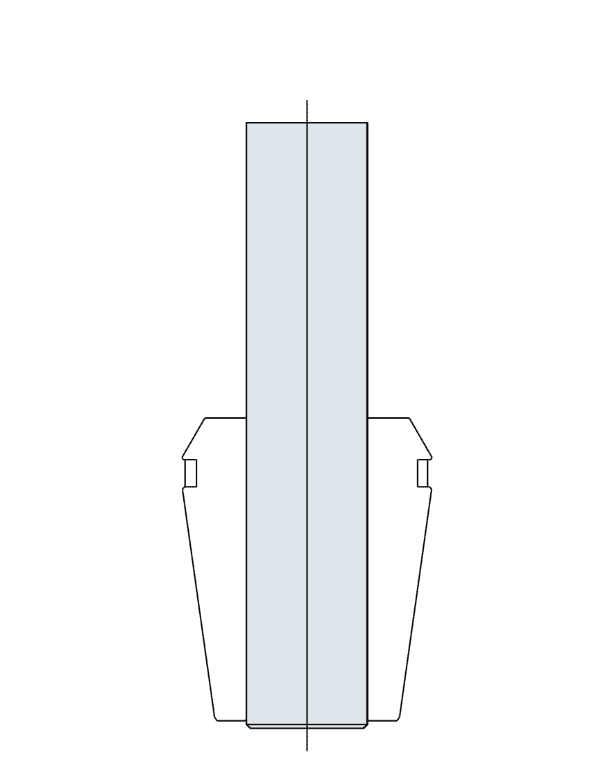

THE PRECISE ALL-ROUNDER (5 µm)

The FAHRION 5 µm collet is a true all-rounder, upgrading all collet chucks and driven tools for CNC milling and turning operations. The collet fits all collet holders per DIN ISO 15488 (formerly DIN 6499) and far exceeds the DIN accuracy requirements.

It handles all machining tasks in chip removal production, such as milling, drilling, countersinking, reaming and thread tapping, in ER holders, driven tools and directly in spindles with an ER taper.

Available in sizes from ER8 to ER40 in all standard diameters (metric/inch), as well as intermediate sizes, the optimal collet is available for every application depending on the required clamping diameter.

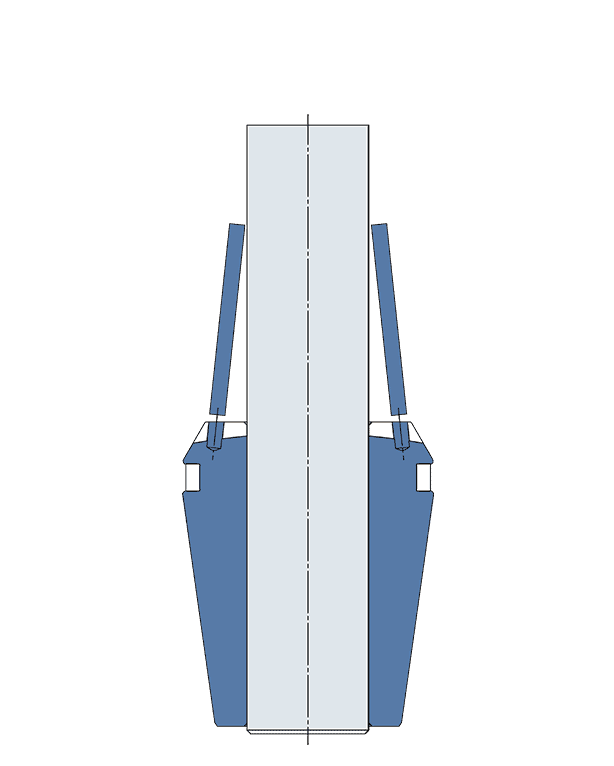

Uncompromising safety – no tool pull-out

No tool pull-out or micro-creeping – 100% guaranteed.

An integrated wedge always engages on the inclined Weldon surface when clamping, creating a form-fit without radially displacing the tool.

-

Higher holding forces

(The tool shank is clamped along three lines, perfectly centring it) -

Optimal damping

(Together with, for example, our Ultra Power Chuck UPC, vibrations during the milling process are reduced) -

Increased tool life

(Better concentricity extends tool life)

Simple handling

To mount, the tool simply needs to be inserted until the wedge engages. To dismount, the tool is briefly inserted, turned and pulled out. The conical compression spring, which is locked into the holder, automatically positions the tool perfectly on the wedge.

Benefits

High concentricity of the collet

Long-lasting precision of tools

Wide range of clamping diameters

Reduced vibrations during machining

Protects the internal taper of the collet chuck

2 µm HIGH-PRECISION COLLET

High interchangeability accuracy

High clamping force

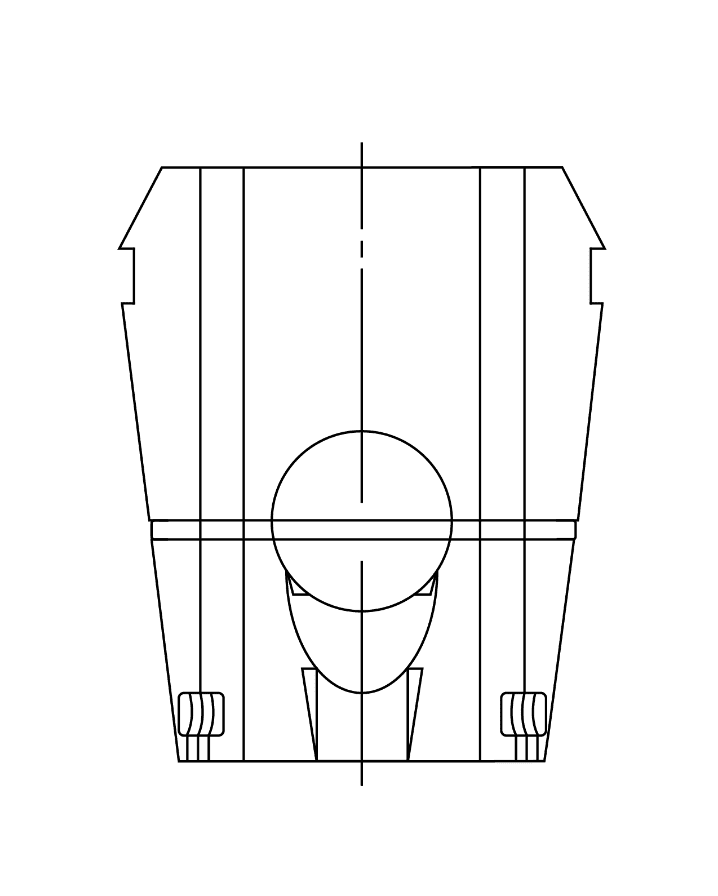

The collets for threading

For smaller threads (M0.5 – M5), a form-fit on the square of the tap is not required due to the low torque. Here, you can use our standard collets, such as the 2.8 mm HP collets for M3 threads.

From a size of M6, we recommend using GB collets with a square fit.

As the cooling lubricant supply (CL supply) plays a critical role during threading and thread forming, FAHRION GB collets are already standardised for internal coolant supply, either through the collet or the tap/thread former.

The thread tapping collets can be used with both DIN and ISO threading tools with the same shank diameter.

Good to know

When do clamping systems based on collets qualify as high-performance clamping systems?

A clamping system must meet the following requirements: Precision and runout accuracy of at least 3 µm / high clamping force for heavy-duty machining applications with high cutting forces / good repeatability for quick tool changes / vibration damping to minimize oscillations, increase tool life, and improve surface finish / a wide range of system components to ensure machining versatility / durability to withstand the demands of high-performance applications and function reliably over an extended period.

Just like the FAHRION CENTRO|P clamping system, which meets all the above criteria.