Milling Clamping Systems

CENTRO|P – An excellent tool that saves money

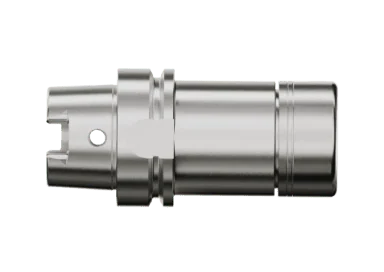

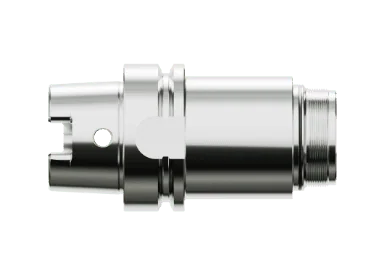

The patented CENTRO|P is a high-precision clamping system of collets, clamping nuts and chucks far superior to conventional collet chucks in all respects. The technological performance of CENTRO|P can be compared with systems such as hydraulic expansion technology, shrink-fit technology or the power chuck technology. CENTRO|P offers you the full range of these technologies – all in one clamping system.

-

A high concentricity of < 3 μm due to special tuning of the cone tolerances

→ Advantage: Less wear, better surface finish, higher speeds, reduced radial deflection forces -

System-based damping through the slots of the collet

→ Advantage: Less vibration, use of higher cutting parameters, more efficient production/shorter machining times -

A constant clamping force, regardless of the tolerance position from bore to shaft, as the cone balances axially

→ Advantage: Process-safe, no tool breakage, no unnecessary machine downtimes -

Proven mechanical clamping/tool holding via a tapered fit

→ Advantage: Maintenance-free, as no media or temperature is used to generate clamping force and durable, as no leaks or material changes can occur.

Success without detours

Thanks to a uniquely clear, targeted design, highest manufacturing quality and consistent service orientation, FAHRION makes your work easier, more efficient, faster and more precise with a comprehensive range of tool clamping systems, making it perfect for demanding production tasks.

FAHRION clamping systems are based on outstanding collet chucks and can handle highly complex challenges. At the same time, we have done everything to ensure that our solutions remain as simple and straightforward as possible for you. This gives you a major advantage in terms of cost-effectiveness.

Milling Clamping System Components

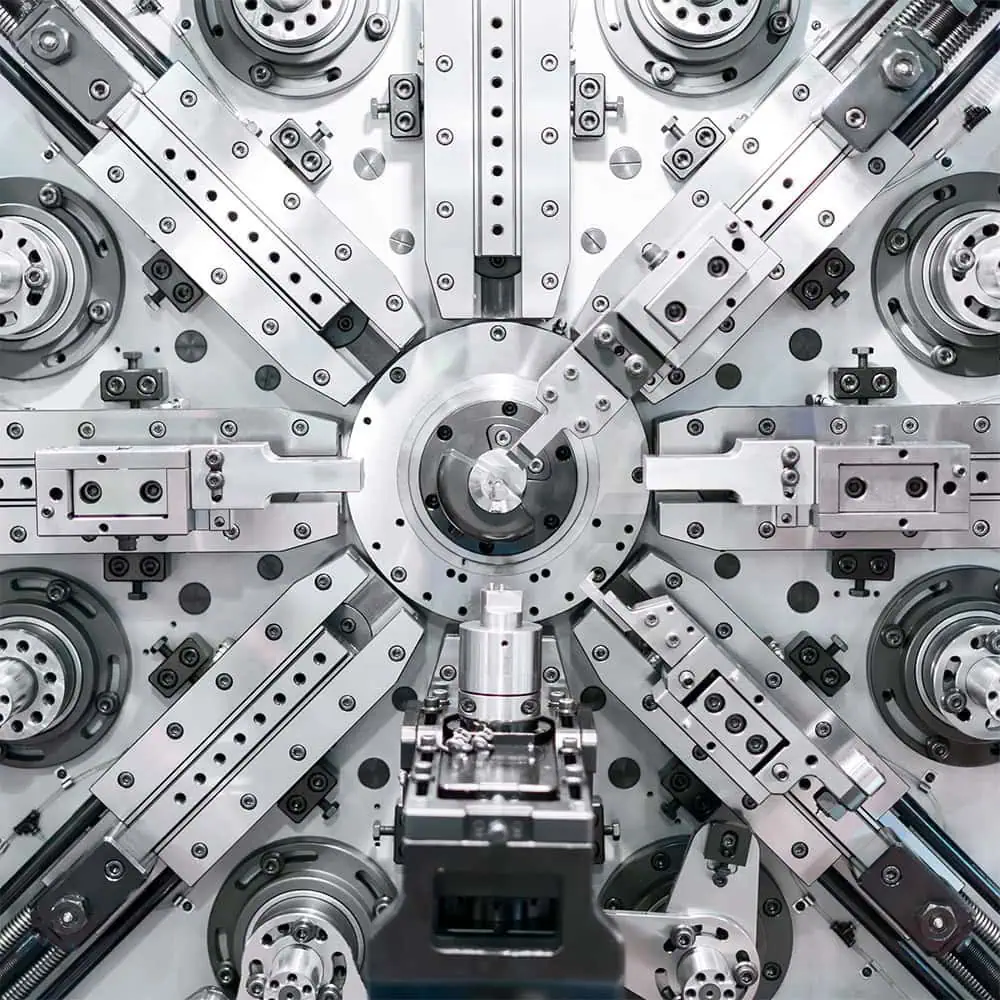

Full flexibility – one clamping system for every application

You can only achieve this with FAHRION: With a wide variety of types including different interfaces, shank forms, lengths and diameters, we offer you a broad range of options for every possible application. By cleverly and easily exchanging just one component, for example, you can immediately respond to new customer requirements.

A clever clamping system, many individual solutions, consistently high FAHRION quality.

Advantages at a glance

- Increased application possibilities

- No more „stopgap“ solutions – always the top solution at hand with consistently excellent results

- Reduced purchasing and storage costs

- Fewer individual parts, yet more combination possibilities

- Increased productivity

- Expanded application possibilities from very small to very large

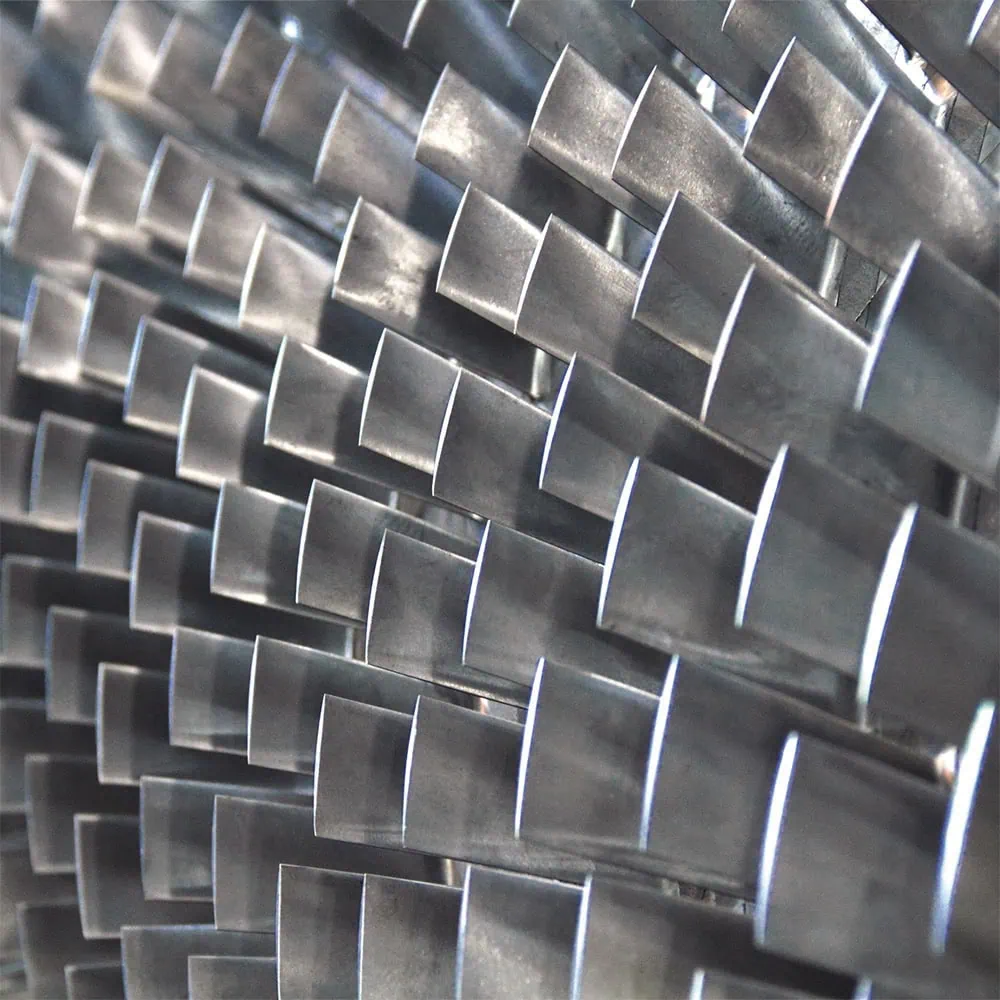

Ultra-precise fine finishing at high speed

Fine and ultra-fine finishing typically involves machines with high-speed spindles, such as high-frequency spindles and accordingly small spindle interfaces. High concentricity and rotational symmetry of the tool holder are particularly important here.

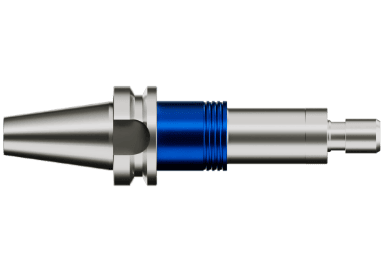

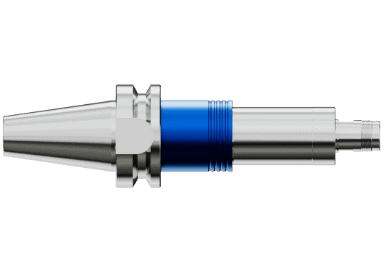

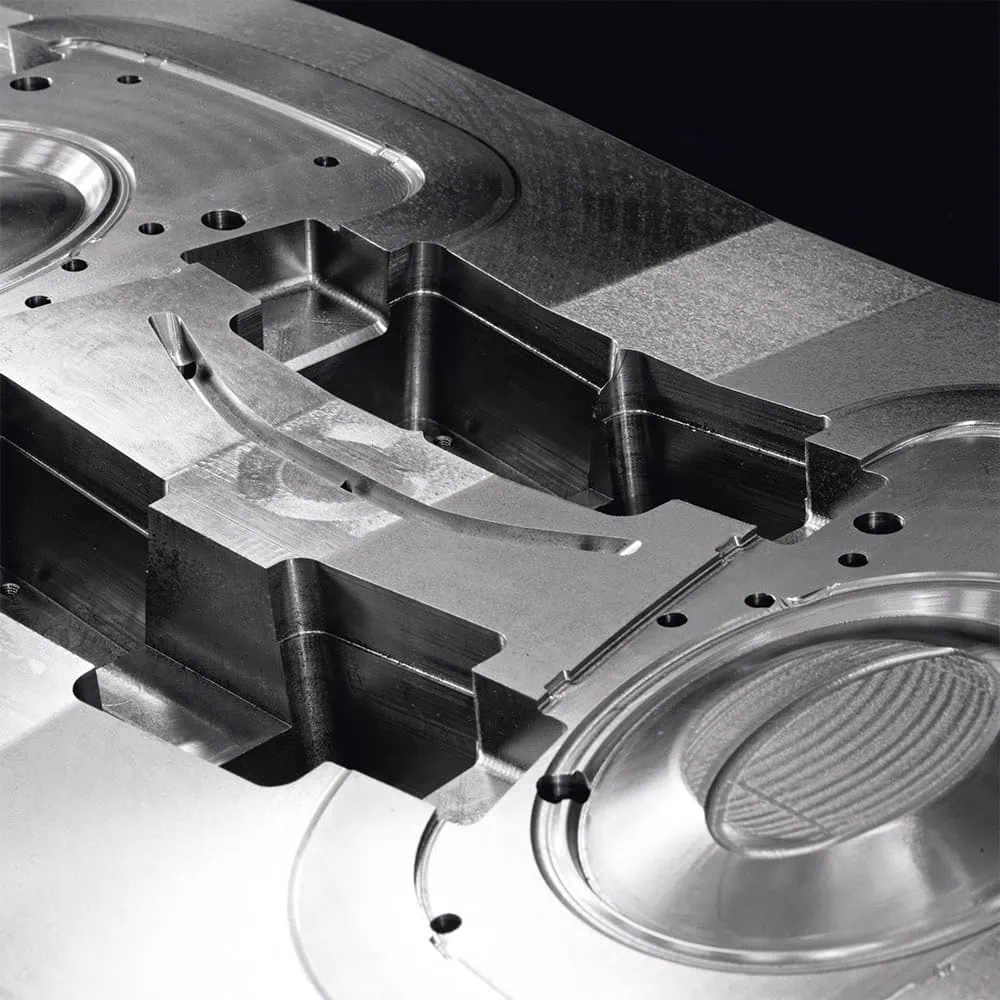

Medical and electrical engineering, as well as tool and mould making or valve and distributor manufacturing, increasingly demand the highest concentricity on high-frequency spindles or deeper plunge depths, while also requiring stable tool clamping. CENTRO|P Mini Precision Chucks (MPC ↗︎) feature small clamping diameters for high speeds and sometimes very slim outer contours, allowing for deep immersion into cavities. Cylindrical shafts can be reliably clamped from a shaft diameter of just 1 mm. The outer diameter starts at 10 mm.

All CENTRO|P Mini Precision Chucks are slim precision chucks with optimal interference contour, making them ideal for high-speed cutting (HSC) operations.

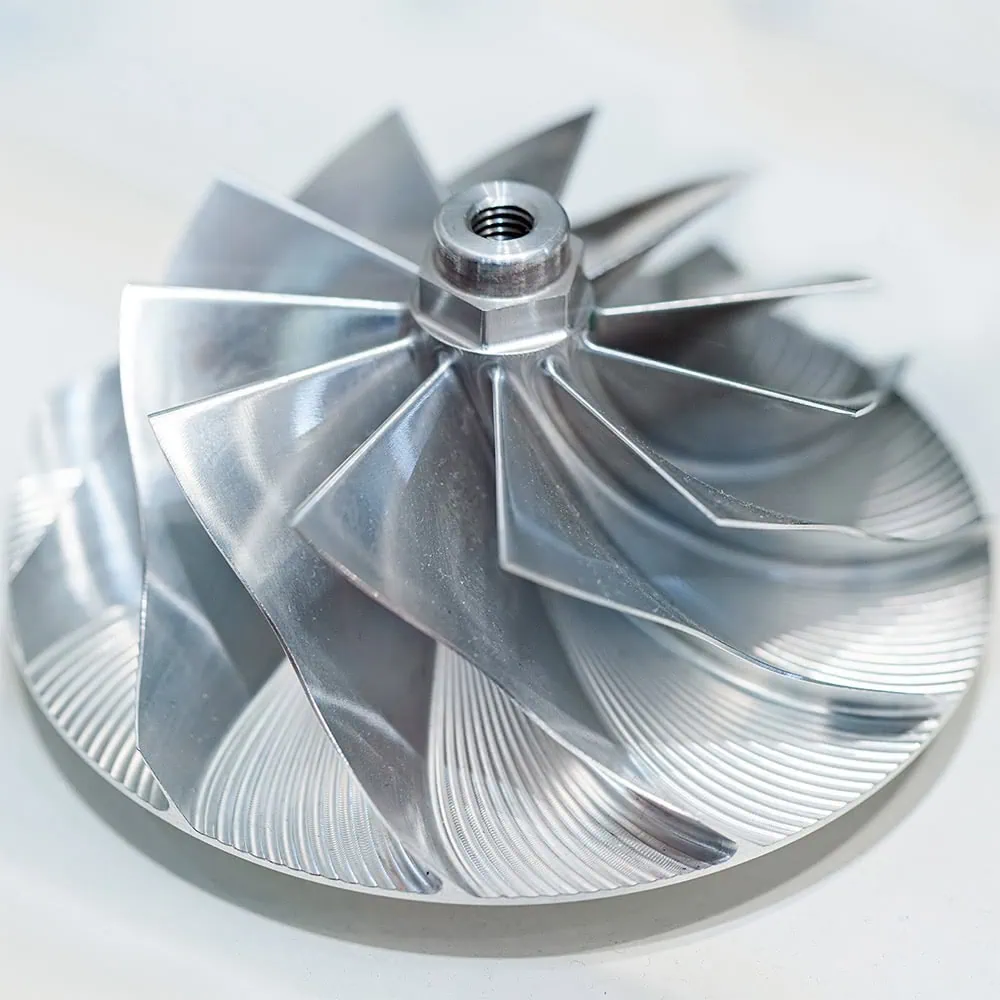

Maximum material removal with trochoidal or high-feed strategies

Maximum material removal is the benchmark in trochoidal or high-feed strategies when milling. High lateral cutting forces, extreme tensile loads and a strong tendency for vibrations due to deflection forces are the biggest challenges. A stiff base construction, good concentricity and the highest possible damping are therefore important criteria for choosing the right chuck. An additional form-fit may be advantageous.

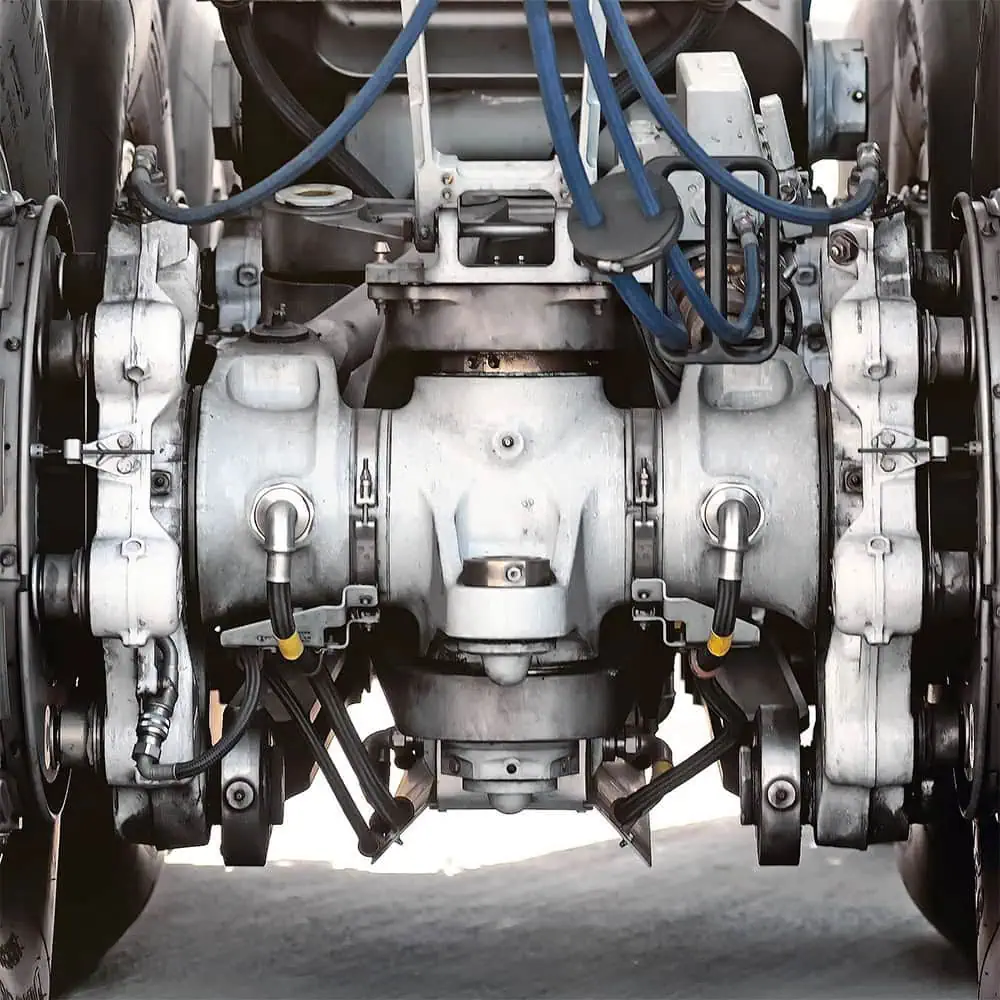

CENTRO|P high-performance chucks UPC ↗︎ (Ultra Power Chuck)/ FPC ↗︎ (Full Performance Chuck) feature a stable base construction and sometimes even a reinforced body for high radial loads. Clamping nuts with specially designed bearings, sometimes in reinforced versions, generate optimal clamping forces and effectively suppress vibrations during milling.

In cases of extreme stress, special collets with integrated pull-out protection can be used when milling, ensuring the required form-fit on the standard Weldon flat surface. Get the maximum performance from your machine.

Good to know

WHAT IS THE ADVANTAGE OF FAHRION CENTRO|P?

FAHRION CENTRO|P is a quality product. Quality comes at a price, but in the long run, the investment will pay off multiple times over. A quality product saves money in the long term.

Our experience in the industry repeatedly shows: Those who cut costs in the wrong places regret it later. The tool holder is the best example of this. Short-term savings may be possible here. But in this case, short-term means short-sighted. If the tool holder does not match the quality of the machine and the cutting tool, the quality of the final product suffers significantly. Saving in the wrong place ultimately costs more money. Specifically, this means: Those who save on collets and collet chucks will sooner or later face a significant drop in quality and turnover.

On the other hand, those who choose FAHRION will get the best possible performance from their machine. Product quality increases and so does the satisfaction of the company’s management. The performance of your high-quality production equipment is significantly influenced by the chuck used as the interface between the tool and the machine. The variety and reliability of FAHRION products ensure that your investments in machines and tools are utilised optimally. With FAHRION, you will realise the full potential of your manufacturing processes.