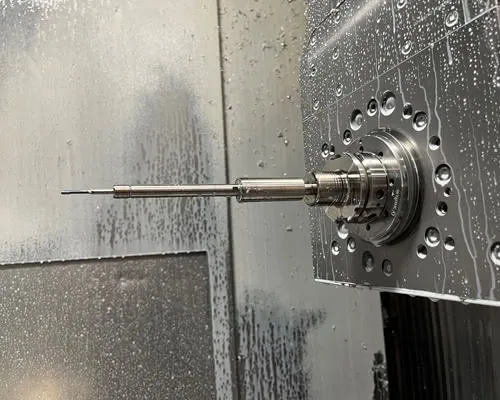

Threading Clamping Systems

THE RUBBER-FLEX-CLUTCH COMPENSATES FOR SYNCHRONISATION ERRORS

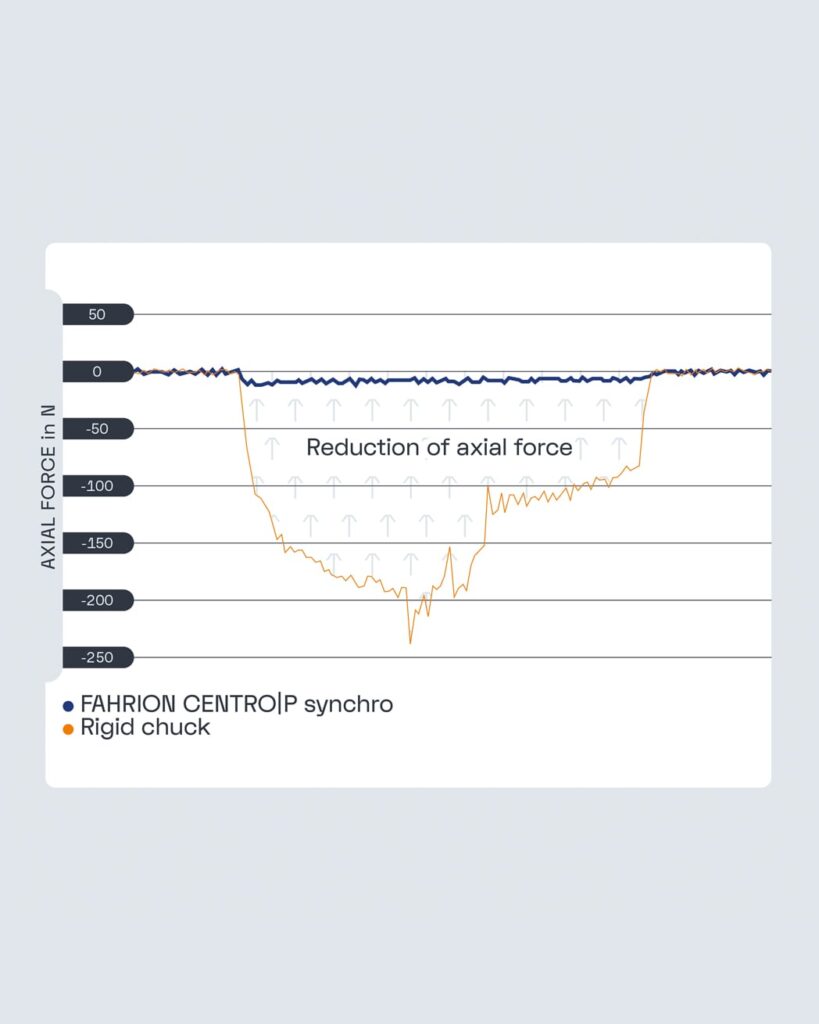

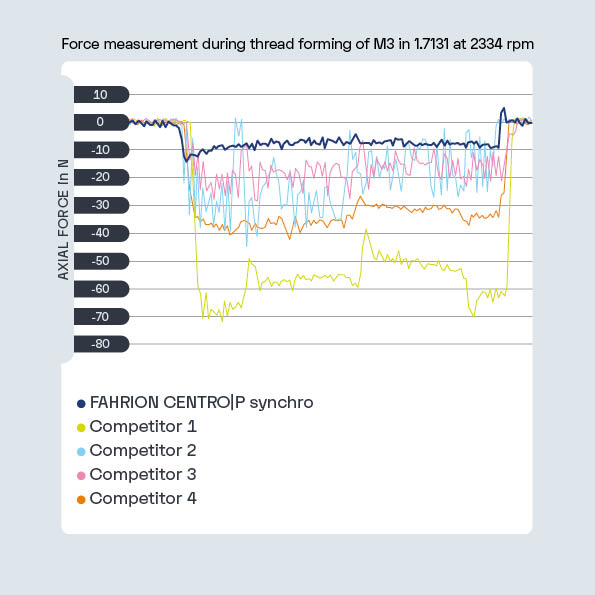

To optimise the process when cutting or forming threads with synchronised machine control, the synchro chuck must maintain axial smoothness, especially under torque load!

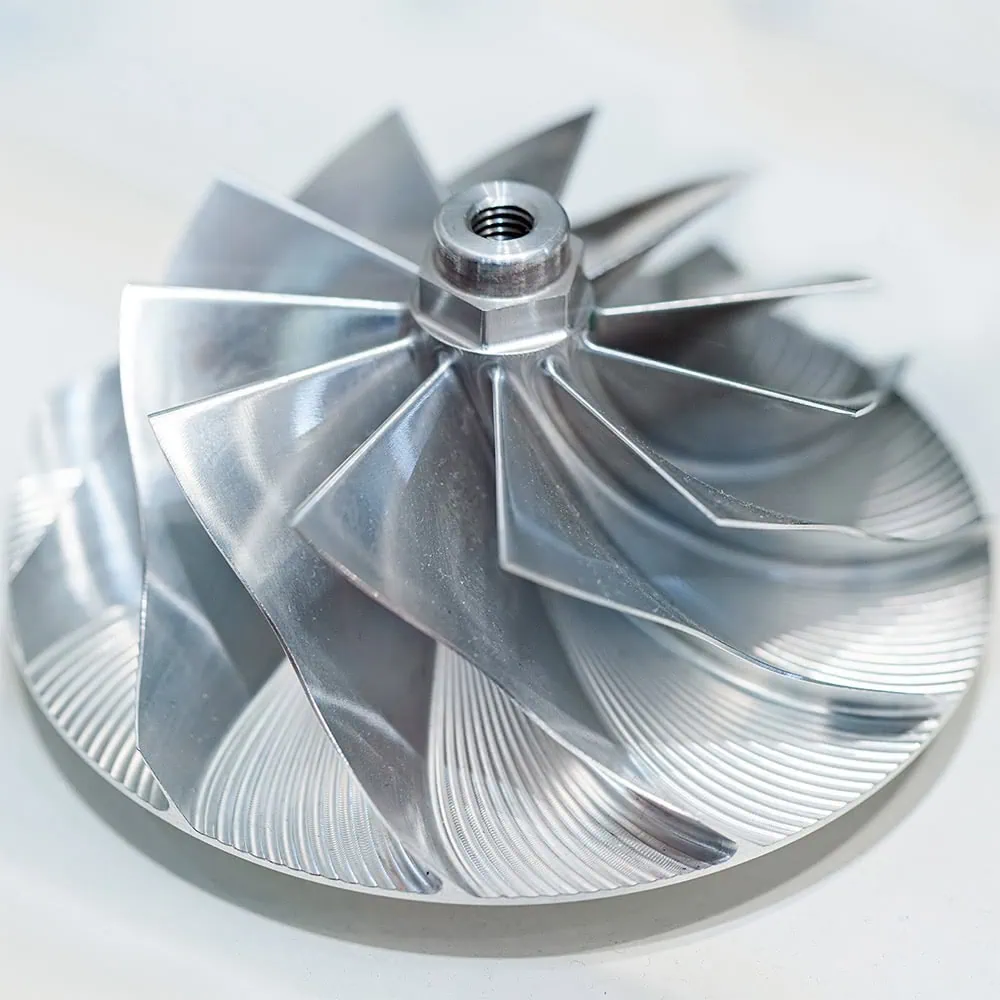

The patented coupling („Rubber-Flex-Clutch“/RFC) is the core of the FAHRION CENTRO|P synchro clamping system. This innovative technology performs length compensation, drive and damping in a single element.

It eliminates the need for traditional mechanical components. As a result, the FAHRION synchro chuck responds consistently sensitively even under torque load, as no friction from mechanical elements can occur.

1. Synchronisation errors from various sources are compensated for.

2. The tensile and compressive forces on the threading tool are minimised.

3. The dampened reversal of the rotation direction significantly extends tool life.

THREADING CLAMPING SYSTEMS COMPONENTS

What a synchro chuck can do

A thread tapping chuck with minimal length compensation („synchro chuck“) works essentially „against“ the axial tensile and compressive forces that occur during thread cutting or forming. Or rather: It works „with“ them. It compensates for any synchronisation errors and keeps the applied forces under control. To safely produce threads, it is crucial that the synchro chuck maintains its smoothness, especially under torque load. However, when the synchronisation of the rotation and feed axes decreases due to wear, temperature fluctuations, tolerances, mass inertia and other factors, the load causes stress, ultimately reducing the tool’s lifespan and durability.

In general:

The weaker the axial force, …

… the better the quality.

… the lower the wear.

… the longer the tool life.

… the safer the process.

FROM reliable problem-solver in critical processes

The FAHRION CENTRO|P synchro chucks ensure the highest process safety. The torque decoupling via the Rubber-Flex-Clutch (RFC) reduces the risk of tool breakage, especially during torque spikes. With high reproducibility of threads, CENTRO|P synchro ensures consistent production quality, which is especially crucial in industries with tight tolerances. Vibrations are effectively dampened, significantly improving the thread surface quality and minimising scrap risk.

To long-lasting performance in large series

Success Stories

Tool life extended by 30% for M3 threads

Customer

Manufacturer of Machine Spindles

Industry

Precision Tools

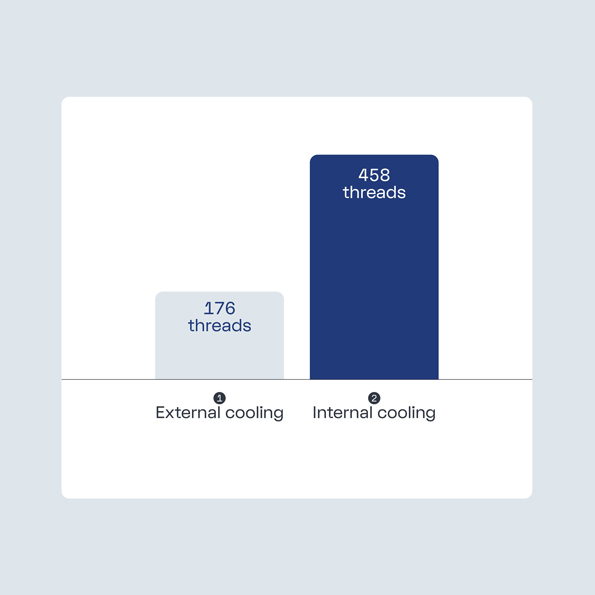

For a customer (a precision parts manufacturer in the electronics industry), we were tasked with significantly increasing the number of acceptable M3 threads.

We achieved this: Compared to two existing synchro chucks (1180 and 1310 acceptable threads), we increased the number of acceptable threads to over 1700. This corresponds to an increase of more than 30%.

| Machine interface: | MAS-BT 30 |

| Material: | 1.0503 / C45 |

| Thread size: | M3 x 0,5 |

| Core hole: | D = 2,53 mm L = 10,0 mm Blind hole |

| Thread depth: | T = 8,0 mm |

| Cutting speed vc: | 30 m/min |

| Cooling/lubrication: | CL outside |

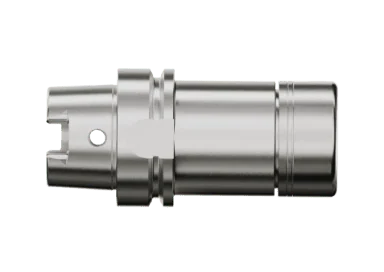

SYNCHRO I

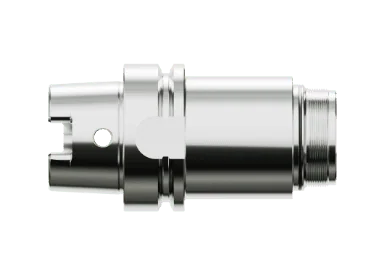

SYNCHRO II

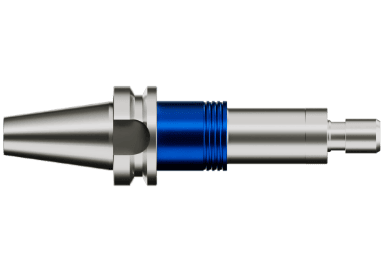

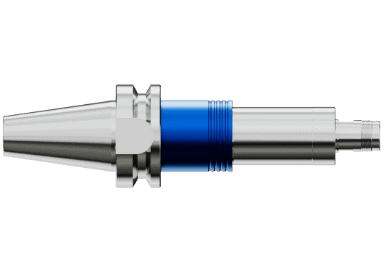

MSC (Mini Synchro Chuck)

Do you have questions about this customer trial, or would you like to make your production more process-safe or efficient?

Feel free to contact us. We look forward to hearing from you.

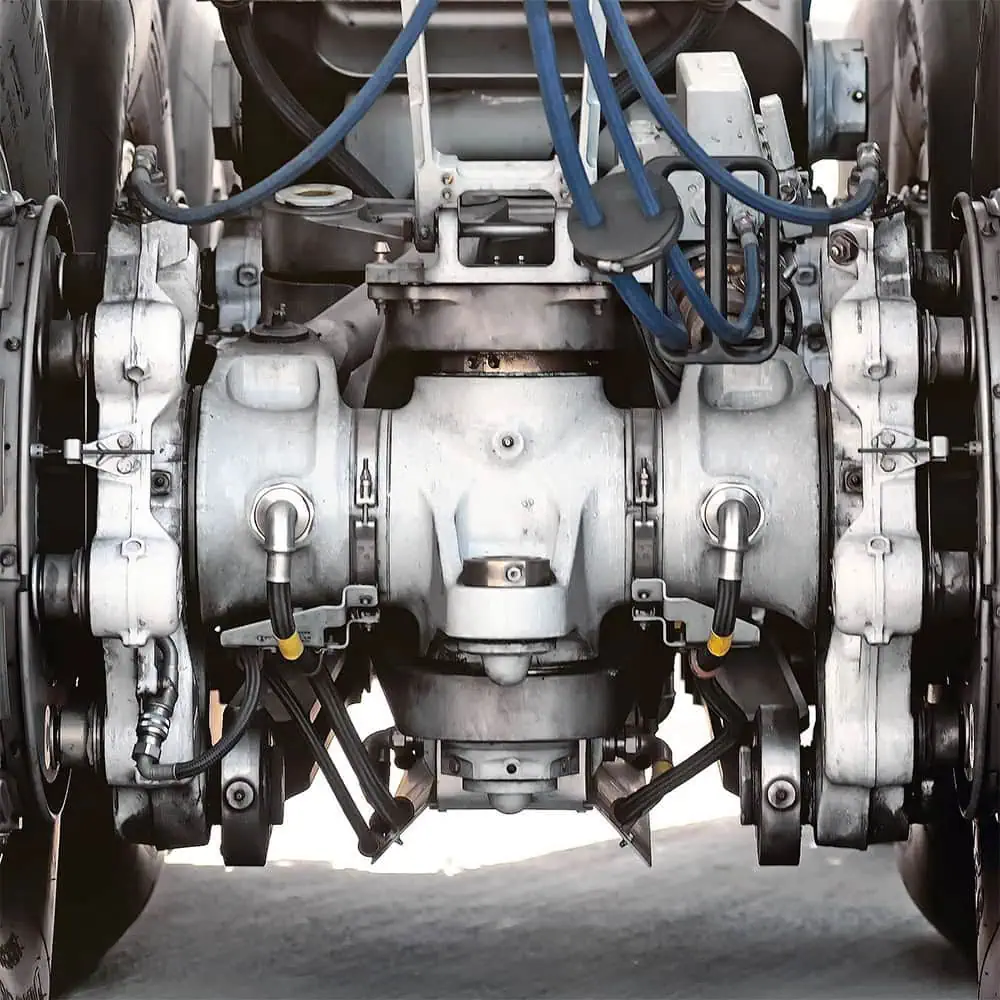

Automated 3-shift production through process safety

Customer

Machine manufacturer

Industry

Mechanical engineering

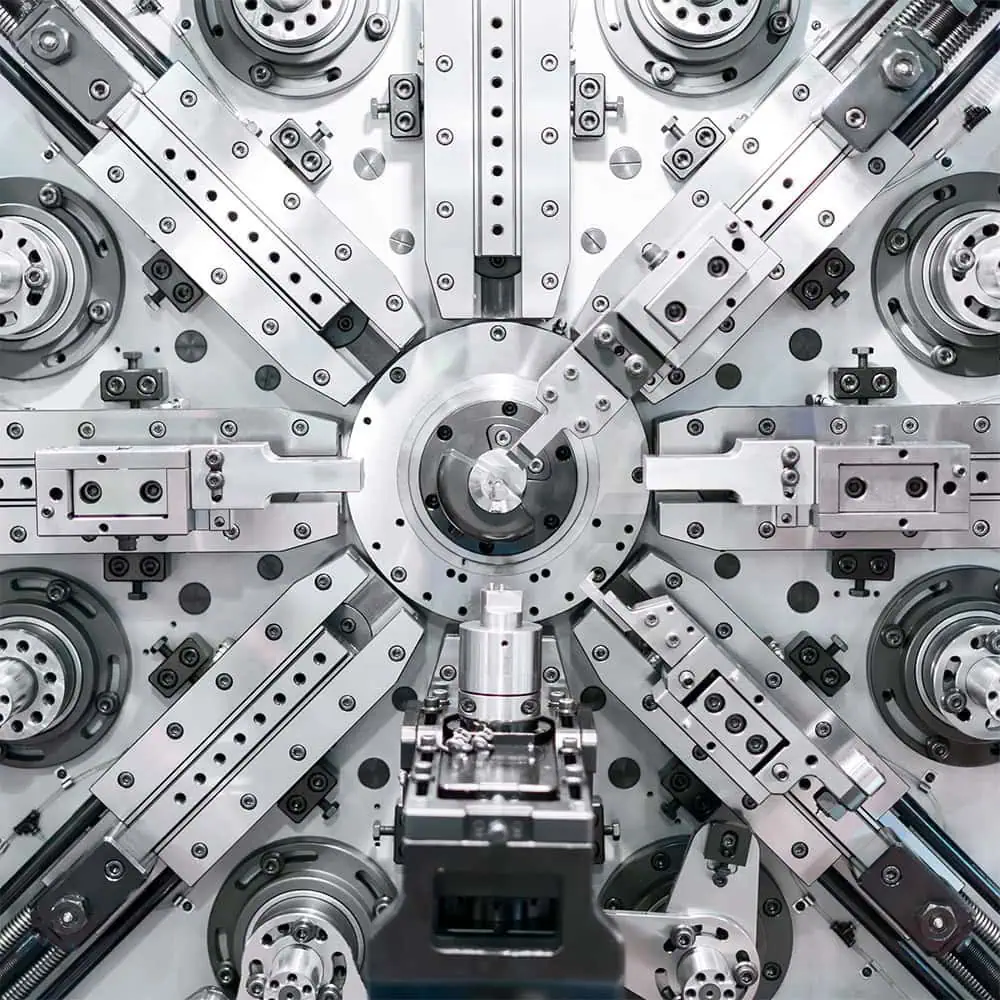

A customer had an unstable process due to regular tool breakage. By using our FAHRION MSC (Mini Synchro Chuck), they were able to ensure process safety in an automated 3-shift production. As a result, they increased the number of acceptable threads to over 3500 before a tool change was needed.

| Machine: | Heller FP4000 |

| Machine interface: | HSK-A 63 |

| Material: | 3.2315 AlSi1MgMn |

| Thread size: | M2,5 + M3 |

| Speed: | 2.000 1/min |

| Cutting speed vc: | 19 m/min |

| Cooling/lubrication: | CL inside + outside |

| Challenge: | Immersion depth |

ACTUAL STATE

TOOL BREAK

TARGET STATE

UNTIL TOOL CHANGE

RESULT USING MSC (Mini Synchro Chuck)

Do you have questions about this customer trial, or would you like to make your production more process-safe or efficient?

Feel free to contact us. We look forward to hearing from you.

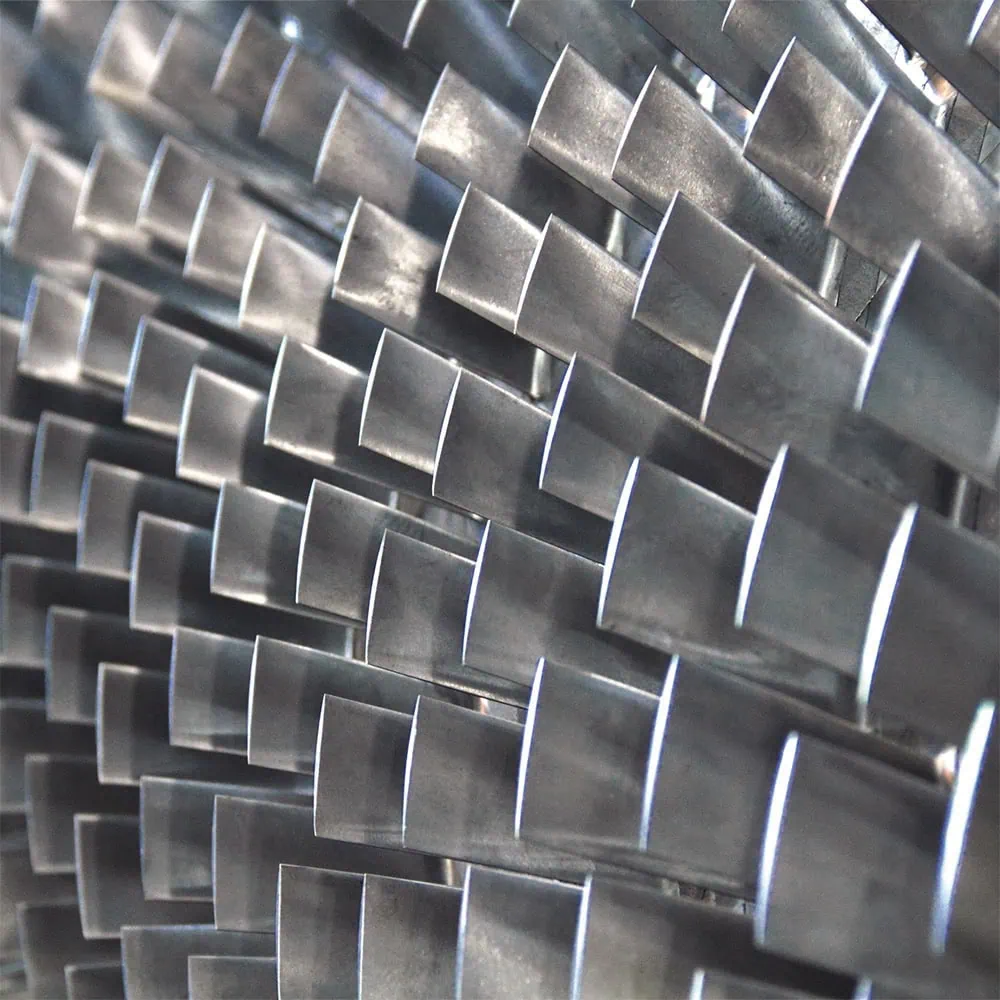

WHAT makes FAHRION different from other synchro chuck manufacturers?

We are the only manufacturer that produces all components of a synchro chuck system based on ER collets (thread tapping chuck body, collet, clamping nut) in-house.