Collet Chucks

With more than 60 spindle interfaces, we definitely have the right solution for you in our CENTRO|P system.

Collet Chuck Facts

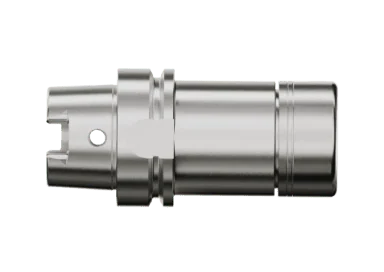

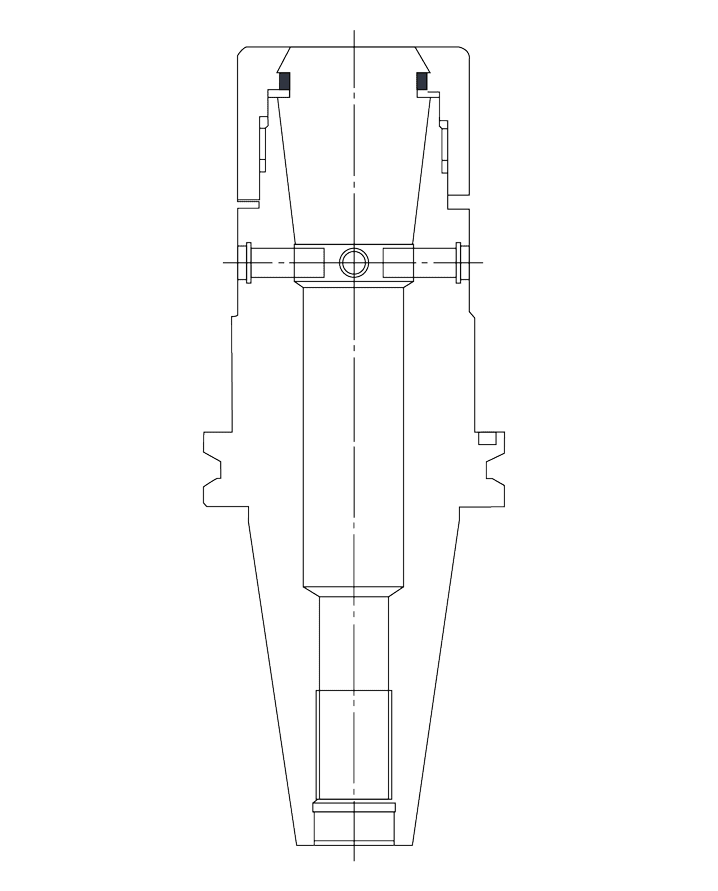

Key Design Features

-

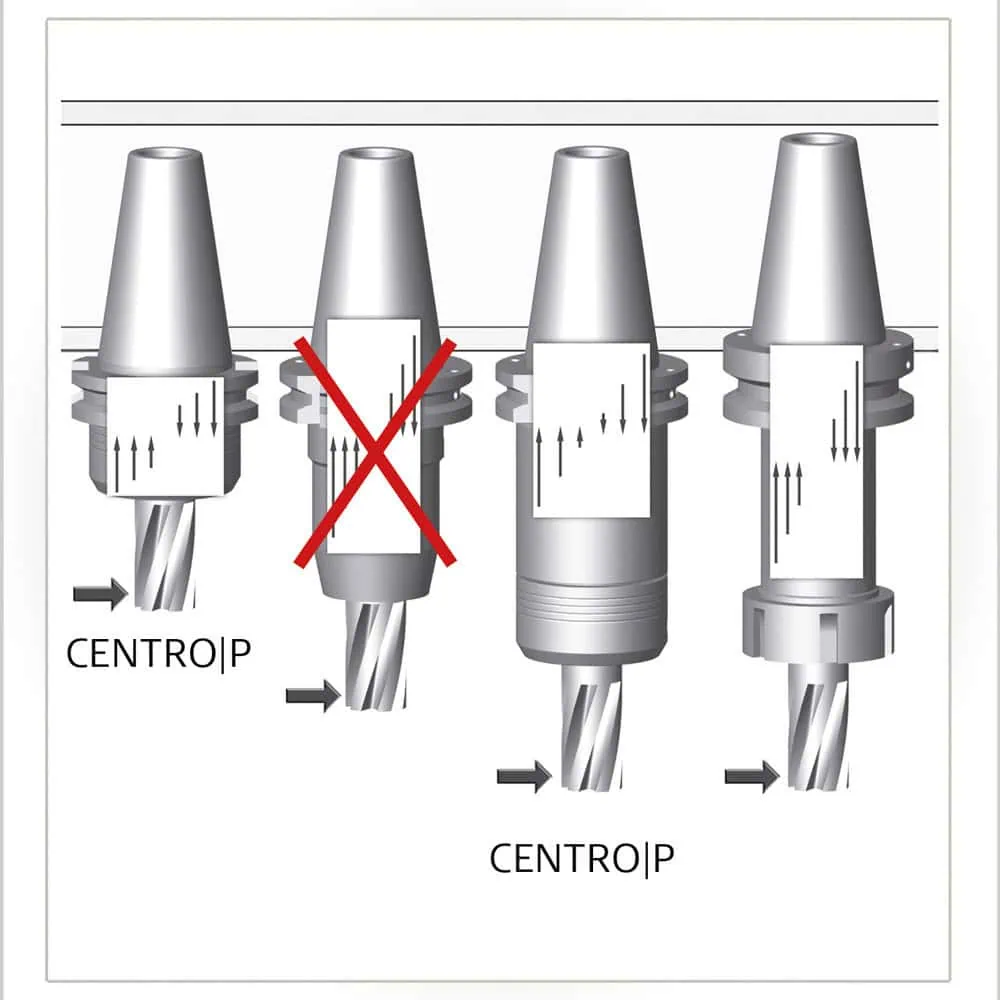

THE COLLET SITS COMPLETELY INSIDE THE CONE

→ The longer guide means {500}greater accuracy and stability -

PRECISELY GROUND DUAL GUIDE FOR THE COLLET NUT

→ While the rear guide centres the clamping nut, the front guide generates an optimal force transfer between the three components when tightening the clamping nut -

A STABLE TRAPEZOIDAL THREAD FOR TRANSFERRING OF THE CLAMPING FORCE

→ As a classic lead screw, the trapezoidal thread achieves a higher resulting clamping force with the same tightening torque -

A CHUCK BODY WITH CONTINUOUS MAXIMUM DIAMETER

→ Maximum stability without increasing the interference contour

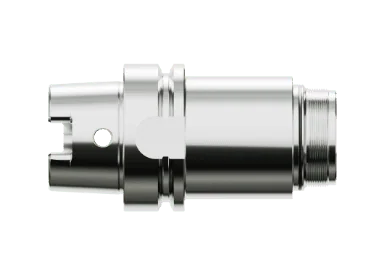

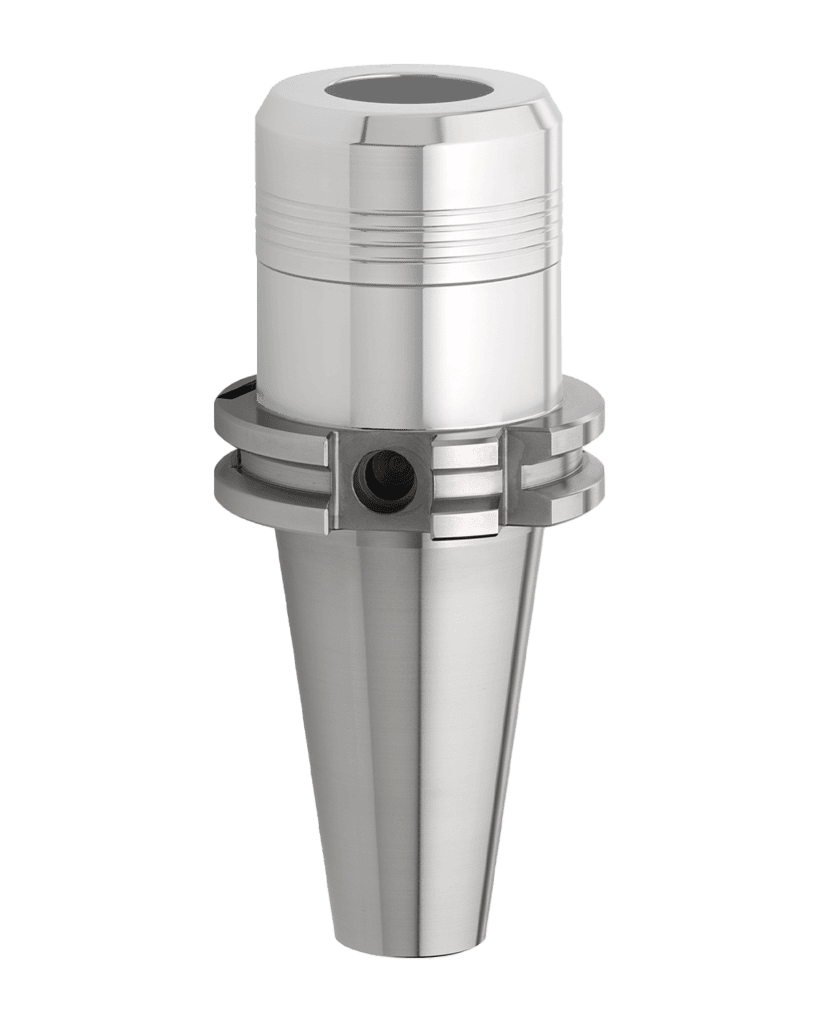

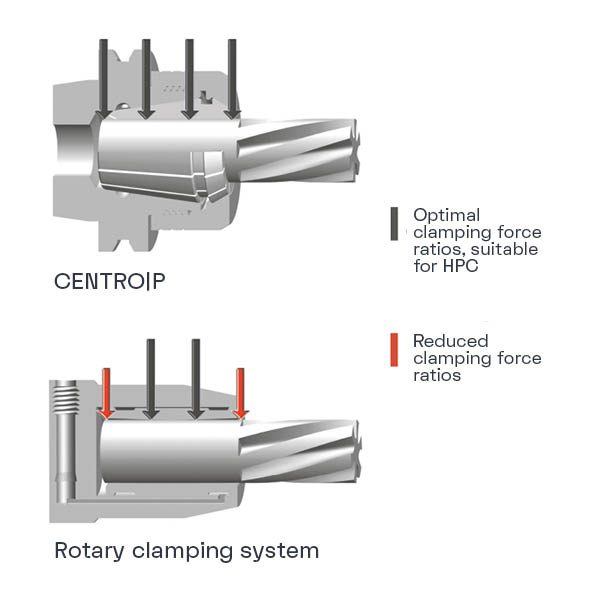

Power Chuck Body UPC (Ultra Power Chuck) / HDC (Heavy Duty Chuck)

A power chuck with an ER collet – is that even possible?

The power chucks UPC ↗︎/HDC are extremely rigid high-performance chucks designed for the most demanding tasks, primarily with radial loads. The wall thickness of the chuck body was increased in order to take more radial force and to suppress the vibrations as best as possible. The uniquely designed trapezoidal fine thread allows the collet nut to be tightened more efficiently. As a result, even higher clamping forces are generated.

Together with other specific system components such as a ball-bearing collet nut and a form-fitting wedge collet, the UPC ↗︎/HDC chuck becomes a superior power chuck using ER collet technology.

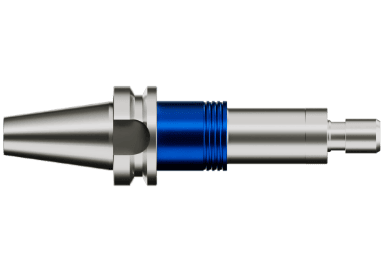

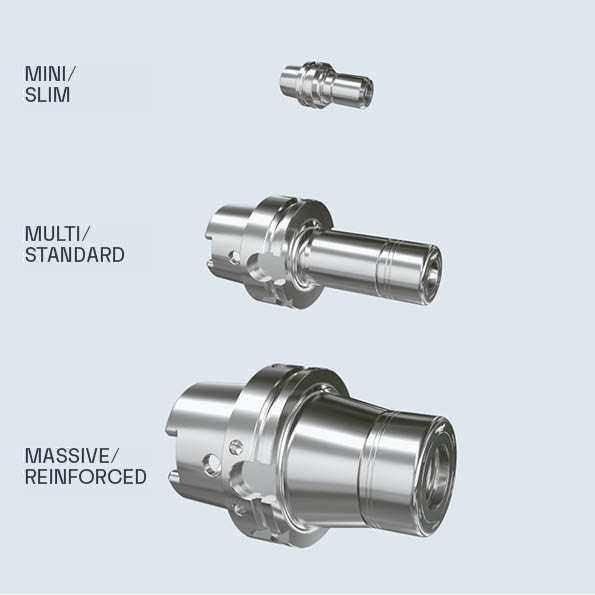

Cylindrical tool extensions

Cylindrical tool extensions ↗︎ are particularly suitable for precise machining in hard-to-reach areas and set new standards in concentricity, setup time and flexibility.

Instead of purchasing expensive custom tools, you can quickly and easily create various lengths for tool holders from existing components. With the CENTRO|P system, a seamless range of lengths from 160 mm to 460 mm is possible.

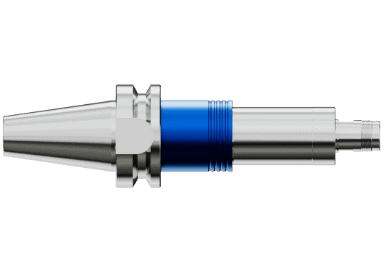

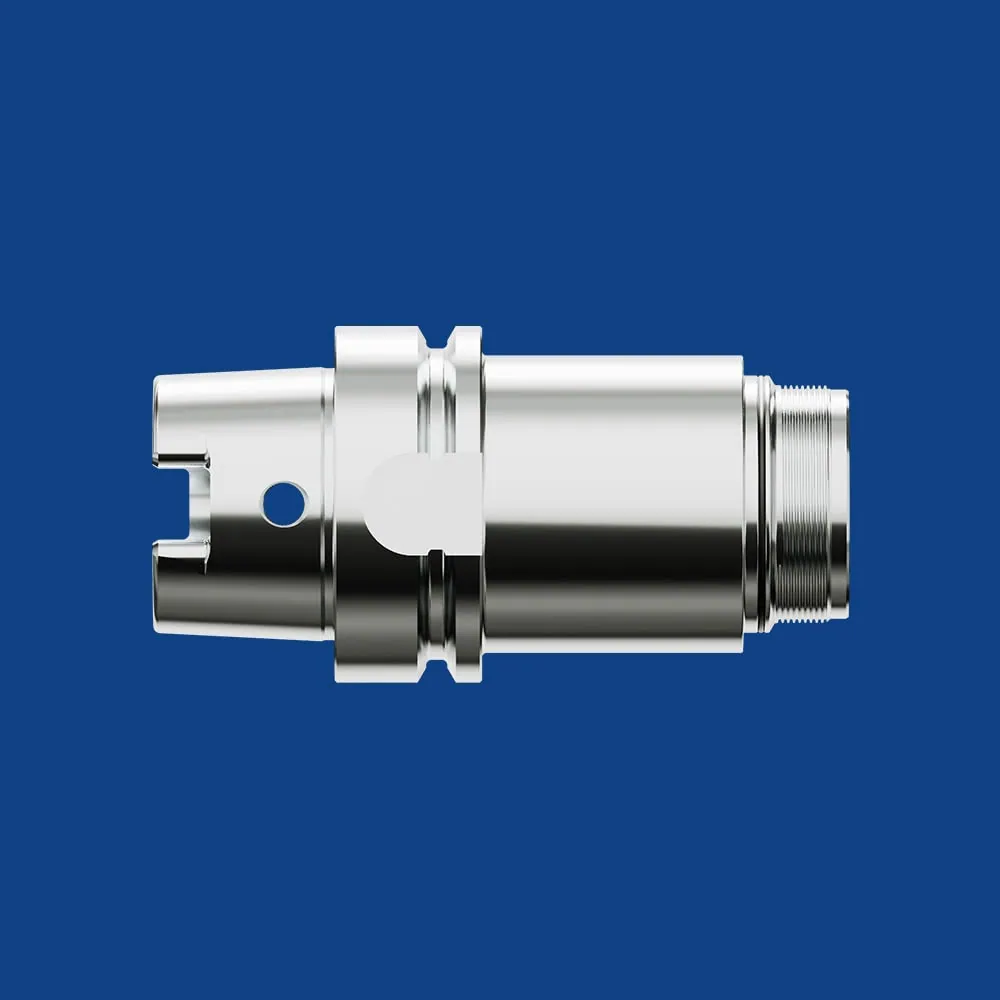

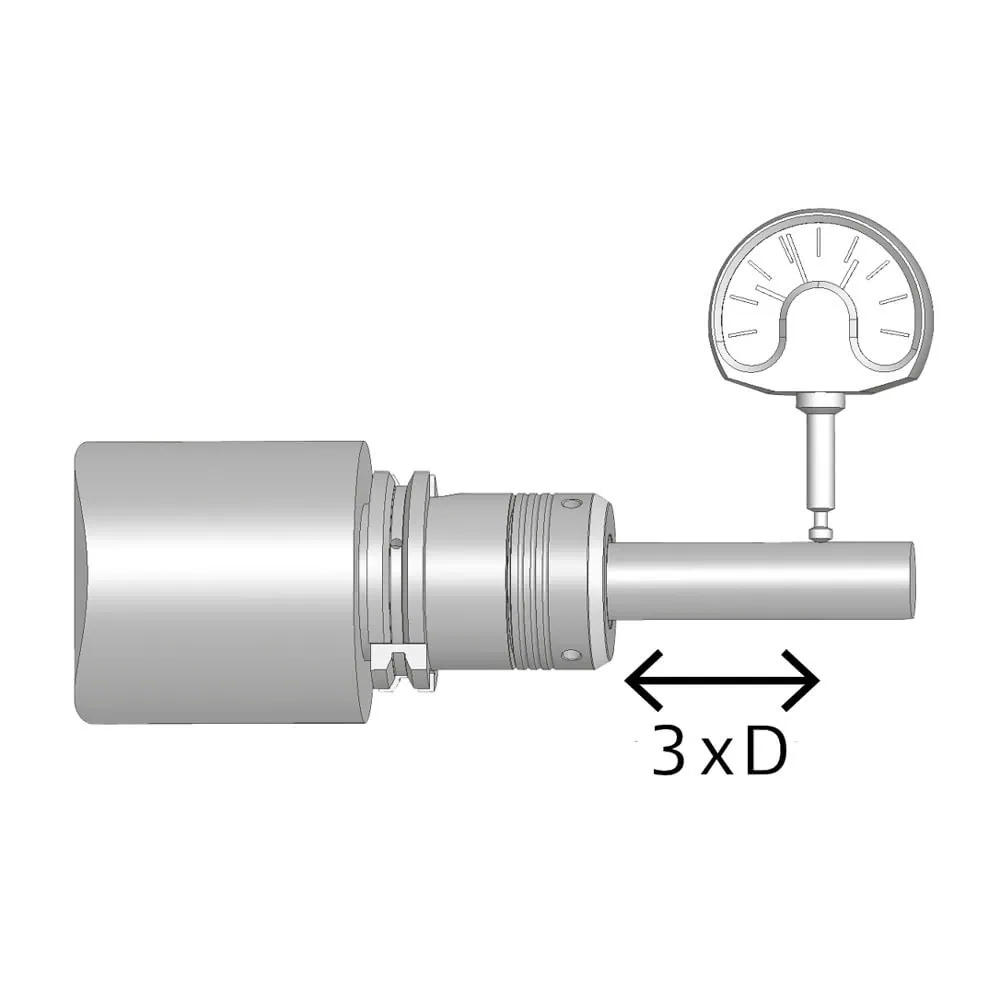

Collet chuck with adjustable runout accuracy

In order to achieve optimal machining results, e.g. during reaming, or also for other ultrafine machining, a perfect concentricity of the tool is essential. Alignment chucks are used to eliminate concentricity errors between the tool holder and the machine spindle.

The adjustable high-precision chucks offer all the advantages of the CENTRO|P clamping system and additionally allow concentricity to be precisely adjusted via four adjustment screws on the circumference of the chuck.

For optimal concentricity, these adjustment chucks must be set directly in the machine spindle.

This is the only way to completely eliminate any concentricity deviations of the chuck and machine spindle as well as faulty interface errors.