FAHRION

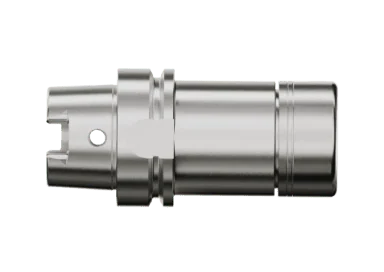

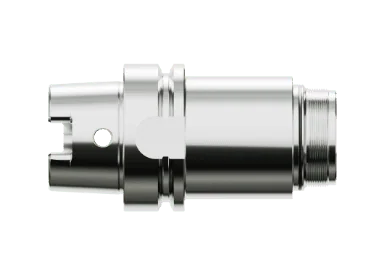

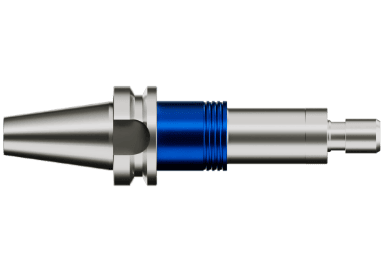

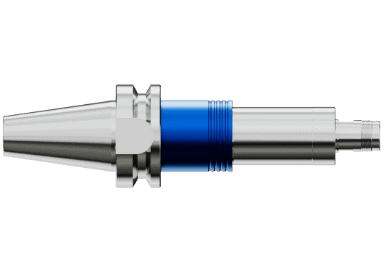

CENTRO|P Clamping Nuts

CENTRO|P Clamping Nuts Overview

without grooves

without grooves

without grooves

without grooves

without grooves

without grooves

applications:

L=11,1 mm

L=16,2 mm

L=20,9 mm

L=23,2 mm

L=23,4 mm

L=21,3 mm*

L=24,6 mm

L=22,8 mm

L=25,6 mm

L=23,8 mm

L=26,9 mm

L=26,9 mm

L=27,0 mm

L=24,9 mm

L=31,5 mm

L=31,5 mm

* HSS: “Mini” version: D = 22.0 mm, L = 20.9 mm; “Tapered” version: D = 24.0 mm, L = 23.2 mm

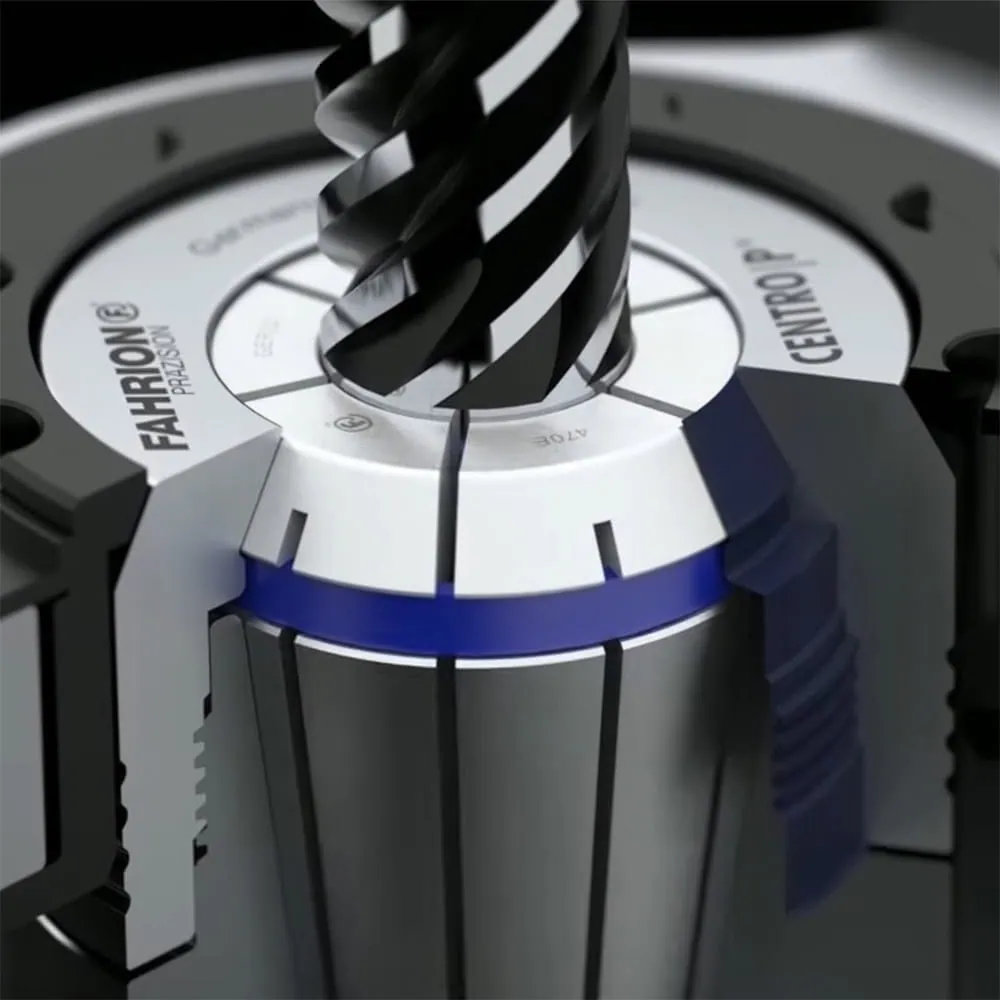

Improved damping

Optimised clamping nut design with angular contact bearings and compensation ring.

As a result, the ball-bearing CENTRO|P clamping nuts achieve a resulting clamping force between 350 Nm and 380 Nm. More than sufficient to prevent twisting of, for example, a wedge collet with pull-out protection.

What is more, the multi-part CENTRO|P clamping nuts enhance vibration damping throughout the system by decoupling the two bearing shells.

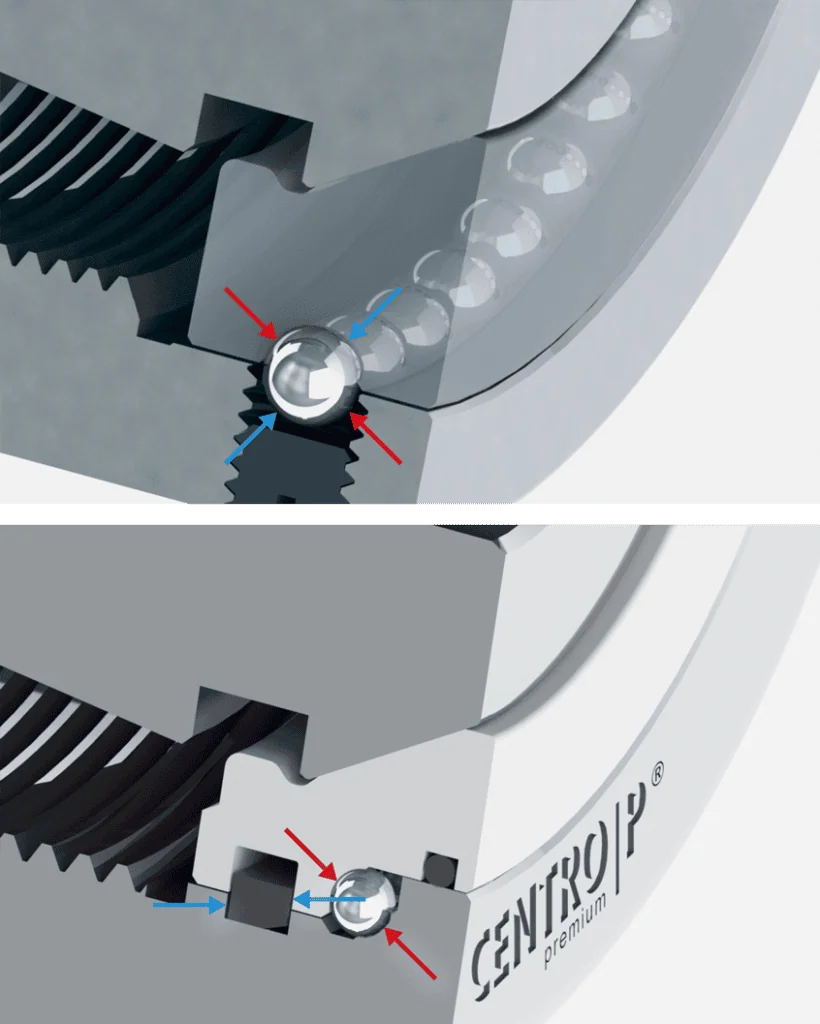

Benefits of angular contact bearings

The compensation ring allows the collet to be clamped without radial forces. When tightening, the pressure on the collet is exerted only in the axial direction from top to bottom.

Conventional clamping nuts with deep groove bearings (top):

→ The force flow during clamping (red) or releasing (blue) is transmitted solely through balls and bearing shells.

CENTRO|P clamping nuts with angular contact bearings (bottom):

→ Power flow during clamping (red) is transmitted via the balls, when releasing (blue) via the circlip.