Chucks UPC - Ultra Power

For Maximum Material Removal Rates

Radial rigidity, compact length and mechanical pull-out protection greater than a holding torque of 1,000 Nm

During processing, oscillation and vibration occur on the machine. These lead to a decrease in the clamping force and to micro creeping, also known as pull-out. Micro creeping occurs in all clamping technologies that do not utilize positive locking techniques.

Very high clamping force usually requires rigid connections, which in turn assists in the formation and propagation of vibration. Micro creeping sets in earlier here. If the connection is less rigid but has a higher damping rate, much better results can be achieved.

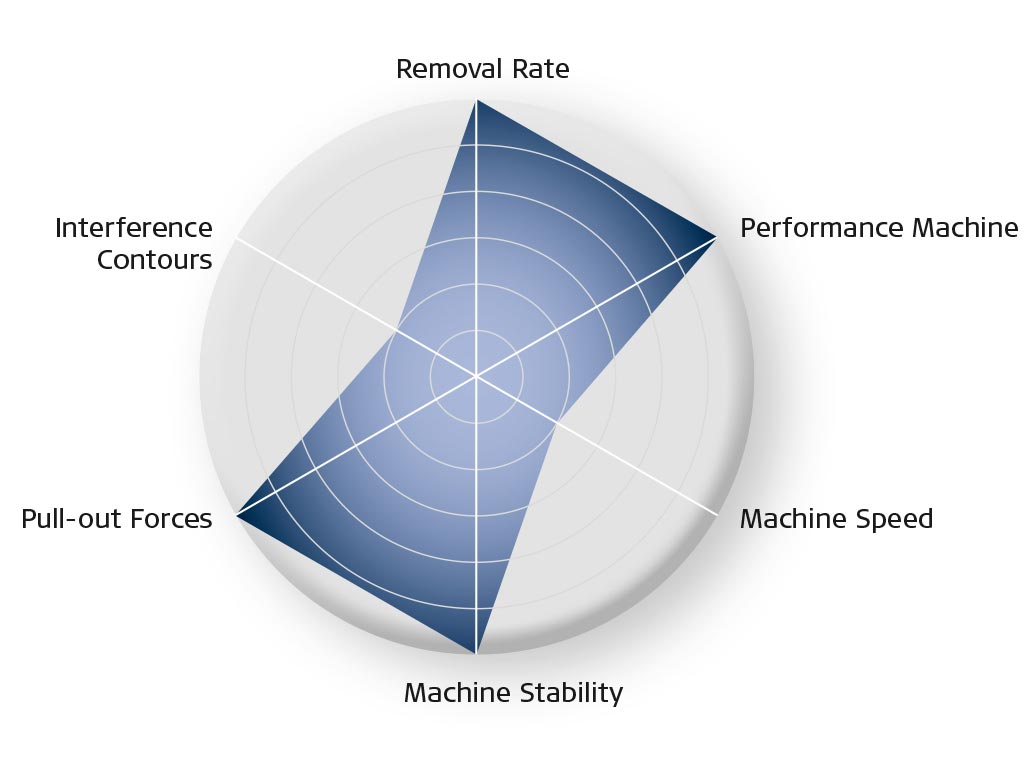

Power chucks, which mainly rely on high nominal clamping force, must accept relatively thin walls of the chuck body. This makes power chucks susceptible to radial stress and vibration. For this reason, our UPC Chucks are built to achieve good damping rates, designed with a stable chuck body, and not focused on the nominal clamping force. Micro creeping is prevented by positive locking.

This Speaks for UPC Chucks:

- Optimal clamping force, so that the collet is unable to slip when clamped.

- Stable basic construction, for the least possible amount of vibrations build up.

- Maximum damping, to effectively suppress vibration that does occur.

- Positive locking over the Weldon surface, which fully prevents micro creeping from taking place.

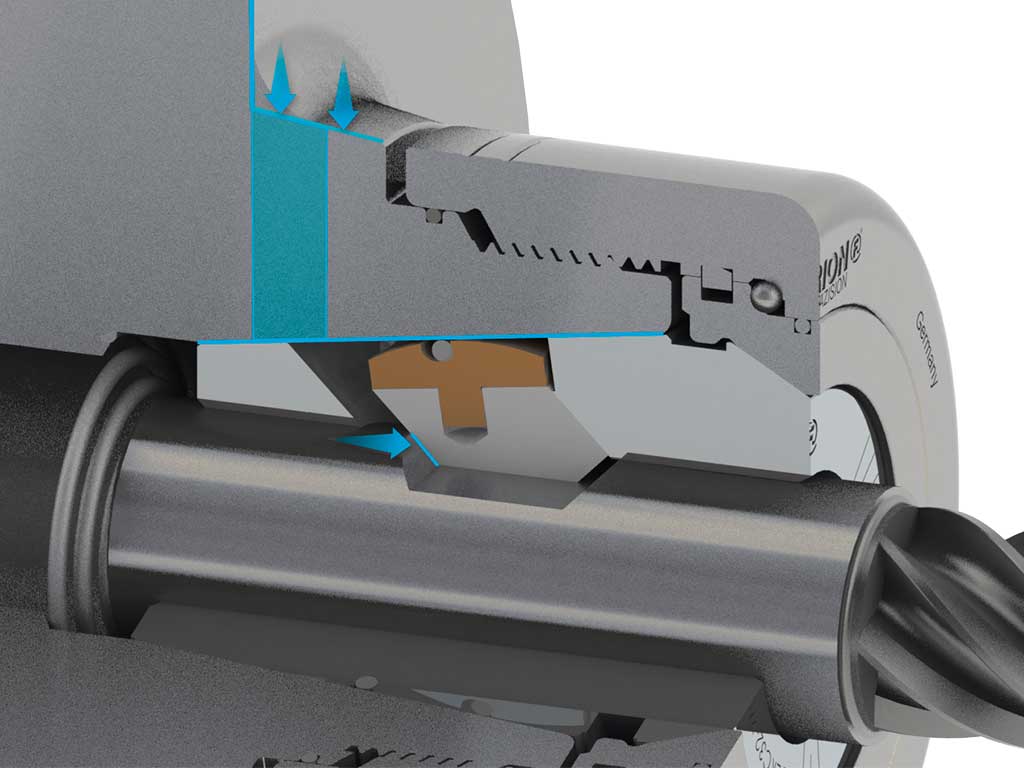

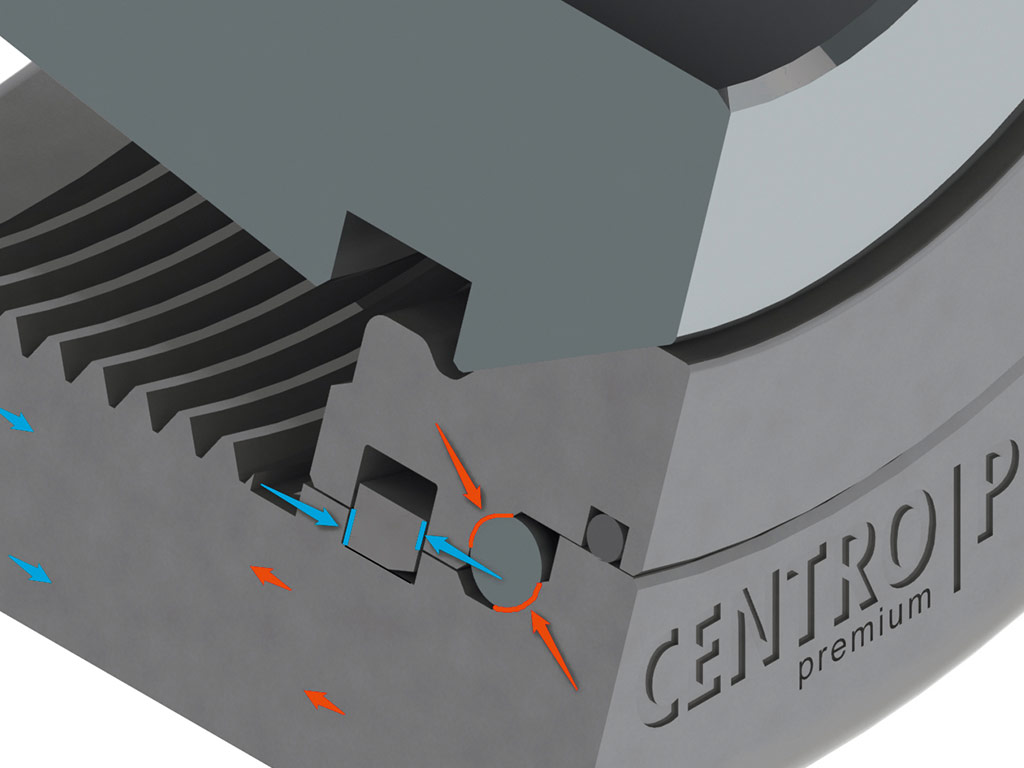

Full performance, thanks to angular contact ball bearings

Despite very good damping properties, the disadvantages of ball-bearing clamping nuts are still present. Only the UPC clamping nut, with its specially developed and patent pending angular contact ball bearing removes these drawbacks.

The unique arrangement of the bearing shells allows for:

- the use of balls with a much smaller diameter. This doubles the number of balls and increases the resulting contact surface. The surface pressure decreases accordingly and impact in the raceways is reduced.

- the decoupling of the clamping and releasing function through a special circlip, which absorbs the entire, sometimes jerky, occurring forces when the nut is open and the collet is pulled out. The bearing raceways are not damaged when applying force during opening.

- the use of hardened bearing steel, which, in contrast to case hardened steel (found in other solutions), counteracts the intrusion of the balls.

- bearing assembly without additional feed opening for the balls. As a result, the balls have no obstacles to block their movement.

- the inclusion of an uninterrupted raceway. This has a positive effect on the residual imbalance and the concentricity properties.

The sum of all these advantages makes FAHRION UPC clamping nut, in all of its main characteristics (clamping force, concentricity and damping), the absolute leader.

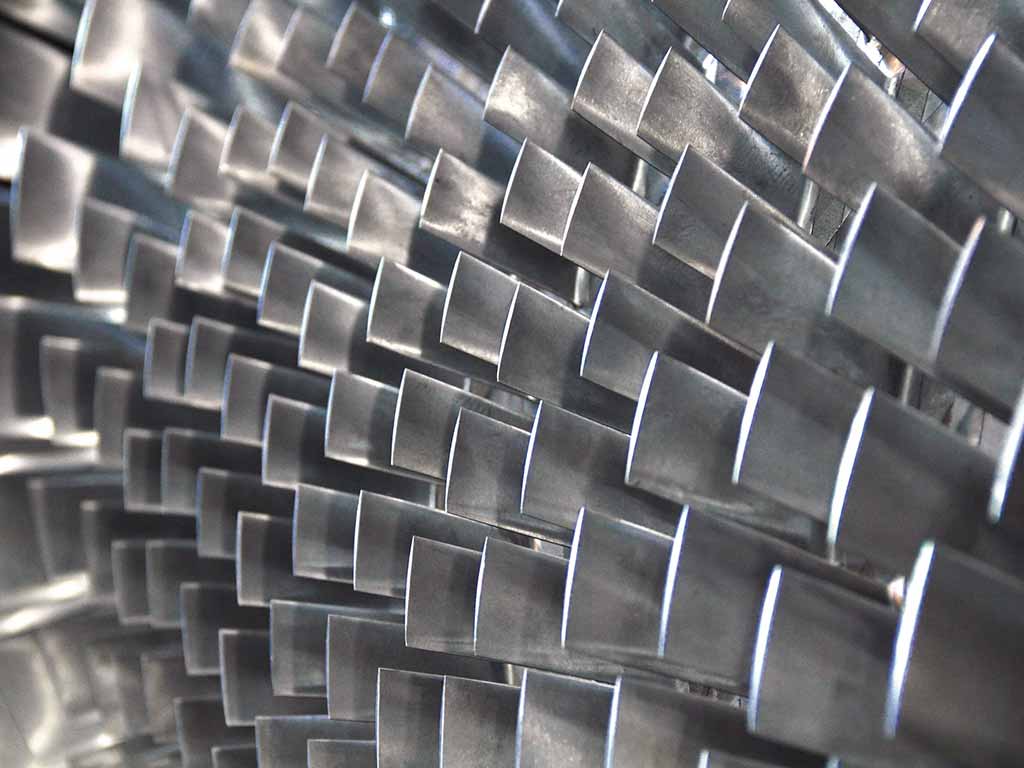

The UPC Chucks are particularly suitable for the roughing of challenging materials, such as:

- Titanium

- Inconell

- Hastelloy

- Heat-treated and Stainless Steels

- Highly Heat-resistant Alloys

Related applications for components found in the fields of:

- Turbine Construction and Energy Technology

- Aerospace

- Medical and Laboratory Technology

- Fluid Technology and Food Industry