GERC and GOZ Collets

The right one for any requirement

Precise

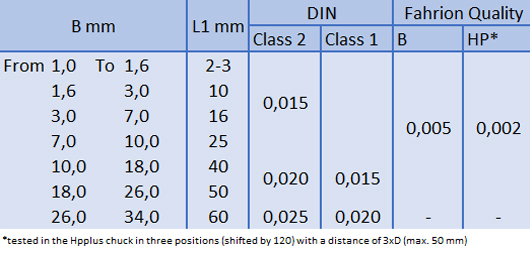

FAHRION collets DIN6499/ISO15488-B (ER/ESX) set the standard of concentricity and repeatability, which is 5μm for the types GER11-B up to GER40-B and 2μm for the types GER11-HP up to GER40-HP.

Rigid

12 slots are sufficient in order to reach the required collapse to DIN6499/ISO15488. This is possible because of a special steel produced for us and a particular harmonized heat treatment. Compared to 16 slot collets, our collets have less tendency to distort.

Saving

All edges are not only deburred, but additionally rounded, which is a prerequisite to protect the inner cone of the collet chuck from marks. Thus, we guarantee consistent concentricity at the highest level.

Thanks to their super-finished execution, our precision collets GER-B and GER-HP offer you the following advantages:

- Increased rigidity and clamping forces

- improved grip

- higher precision and system concentricity

- enhanced resistance to corrosion

What do you gain?

- Increased tool working life, lower tool costs, less setting up time —> Lower production costs

- Better surface finishes and tighter production tolerances —> Improved quality

Effect of runout on the cutting edges:

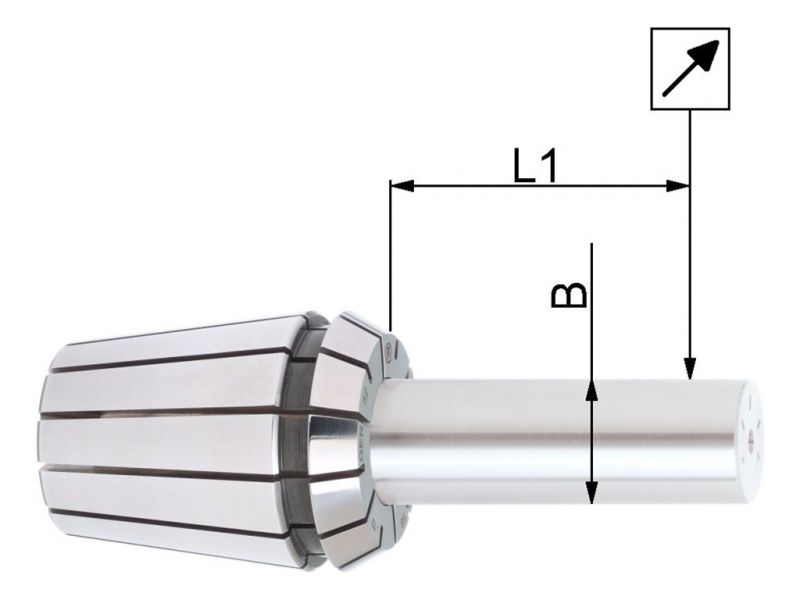

Concentricity for collets DIN ISO15488 (ER/ESX)

The tolerances are classified to DIN into two classes:

- Class 2 is our standard for forms K2 and ET

- Class 1 (higher TIR) is our standard for forms D and GB

- FAHRION quality is our standard (average concentricity with a repeatability of 5μm resp. 2μm) for forms B and HP

Test method (except for HP) see below:

For applications which require highest concentricity, it is absolutely necessary to pay attention to the complete system (machine spindle, collet acceptance, clamping nut, collet and cutting tool).

for a carbide drill Ø 12 mm with collet DIN SO15488- GER32-B (470 E)

Example 1: system concentricity ≤ 10 μm

Cost of a carbide drill: approx 80 EUR

Cost FAHRION GER32-B collet with concentricity 5 μm: approx. 17 EUR

Cost on basis of tool life of approx. 150 %: approx. 97 EUR

Example 2: system concentricity 25 μm

Cost of a carbide drill: approx. 80 EUR

Cost CER32-K2 collet class 2 with concentricity 20 μm: approx. 8 EUR

Cost on basis of tool life of approx. 55 %: approx. 88 EUR

Cost for similar tool life of approx. 150 %

More than two carbide drills necessary! approx. 238 EUR

Result: Cheap collets almost triple the costs!