Tapping

Chucks

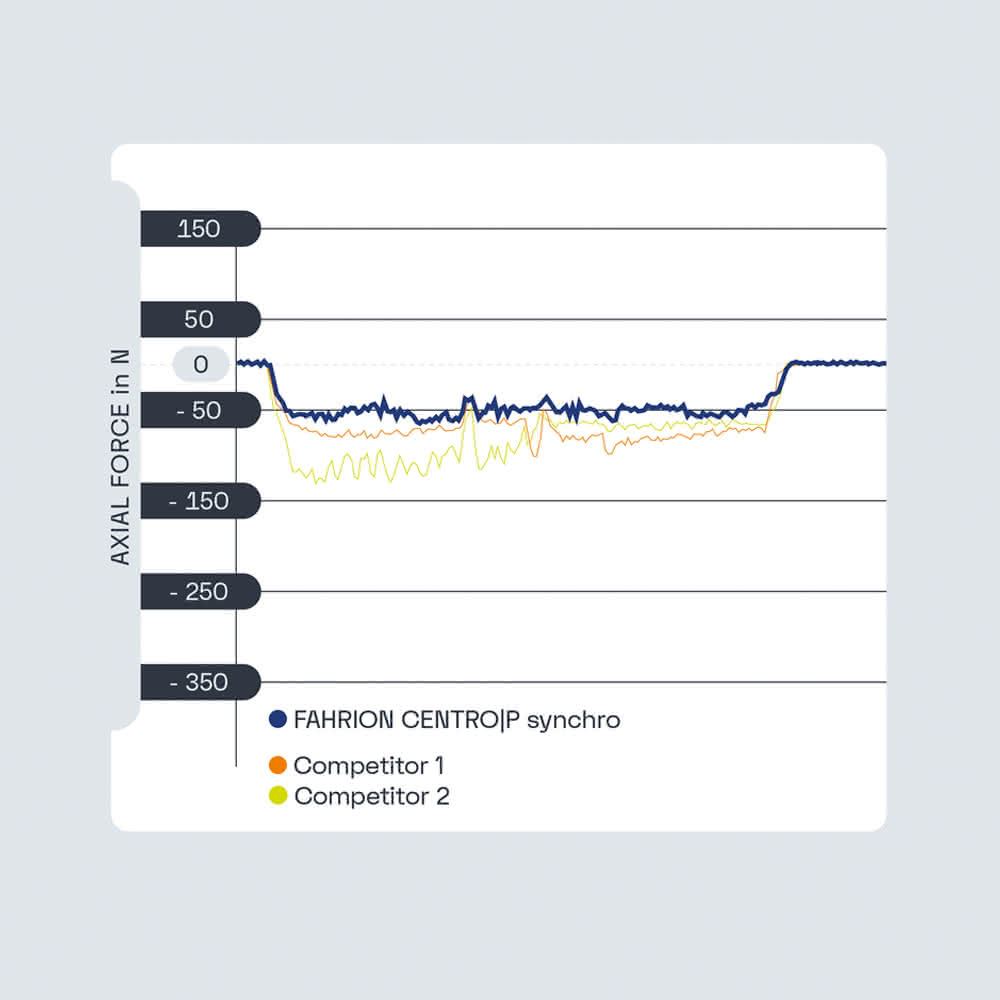

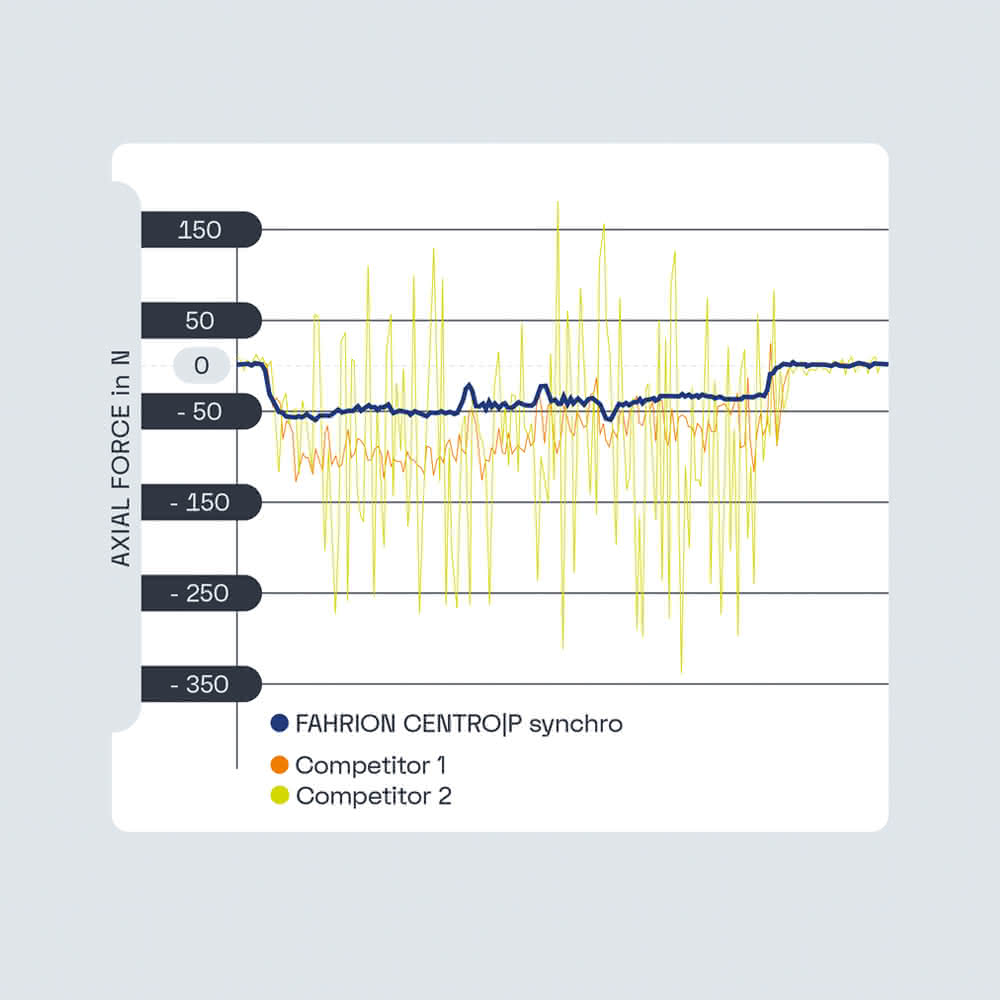

The perfect synchronisation compensation in the Rubber-Flex-Clutch (RFC) ensures that the axial smoothness is fully decoupled from the torque load.

Tapping Chuck Facts

Sensitive response

Optimal cooling lubricant supply

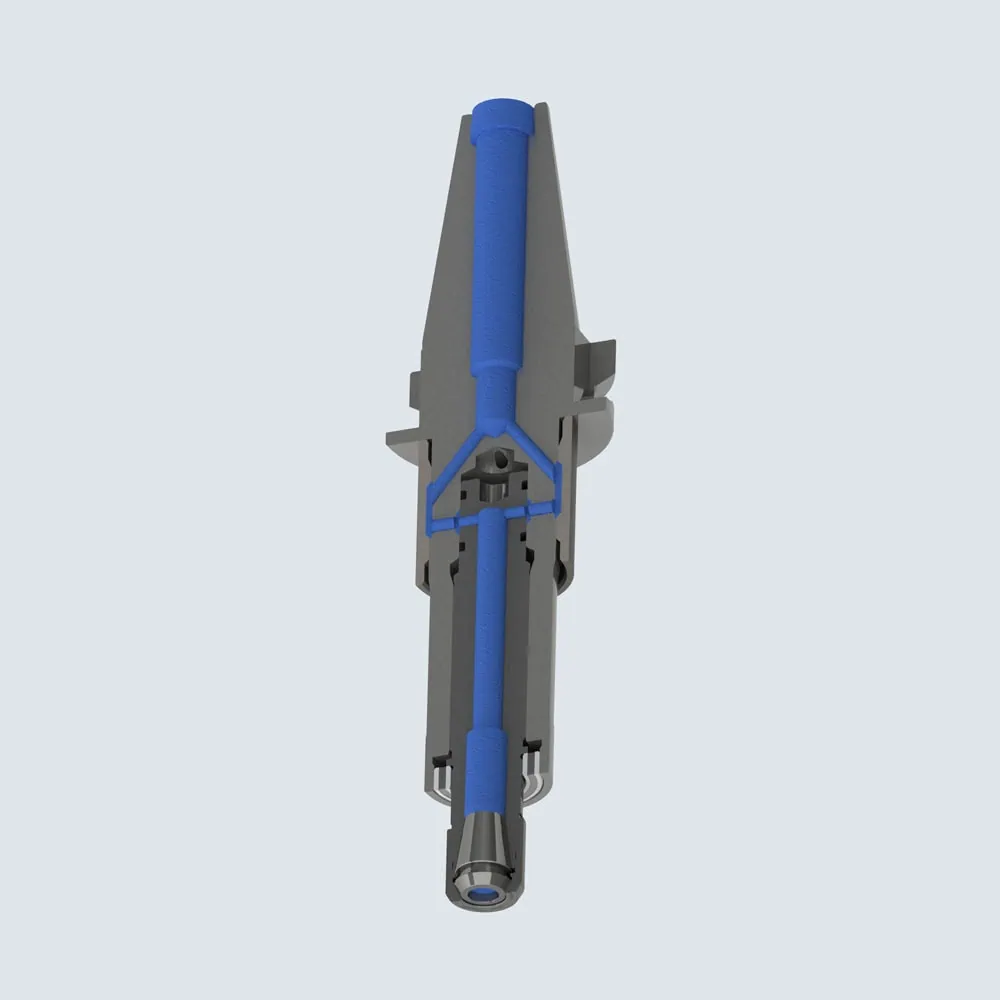

from… SYNCHRONISATION COMPENSATION IN 4 AXES

→ TENSILE AND TORSIONAL FROCES DURING THREAD CUTTING AND FORMING

The RFC acts on the radial drive in the direction of rotation as well as on the axial compensation in both tensile and compressive directions.

→ TORSIONAL AND COMPRESSIVE FORCES AFTER DIRECTION REVERSAL

The RFC acts on the radial drive in the opposite direction of rotation and on the axial compensation in both tensile and compressive directions.

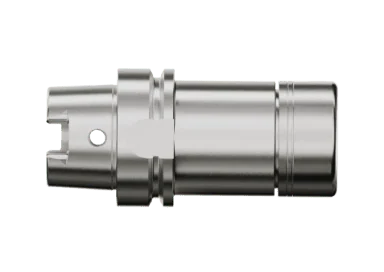

to… PLAY-FREE SYNCHRONISATION COMPENSATION

The perfect interplay of the highly precise individual components ensures maximum concentricity. Special attention is given not only to the accuracy but also to the length of the guide rails.

In general, the longer moving parts are guided, the more stable the accuracy is maintained. CENTRO|P synchro thread tapping chucks stand out compared to other systems due to these extra-long guides while maintaining FAHRION’s high quality.

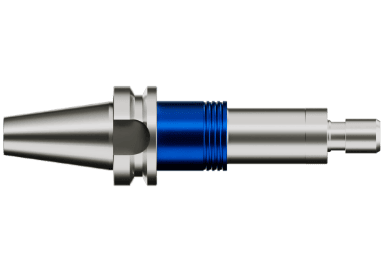

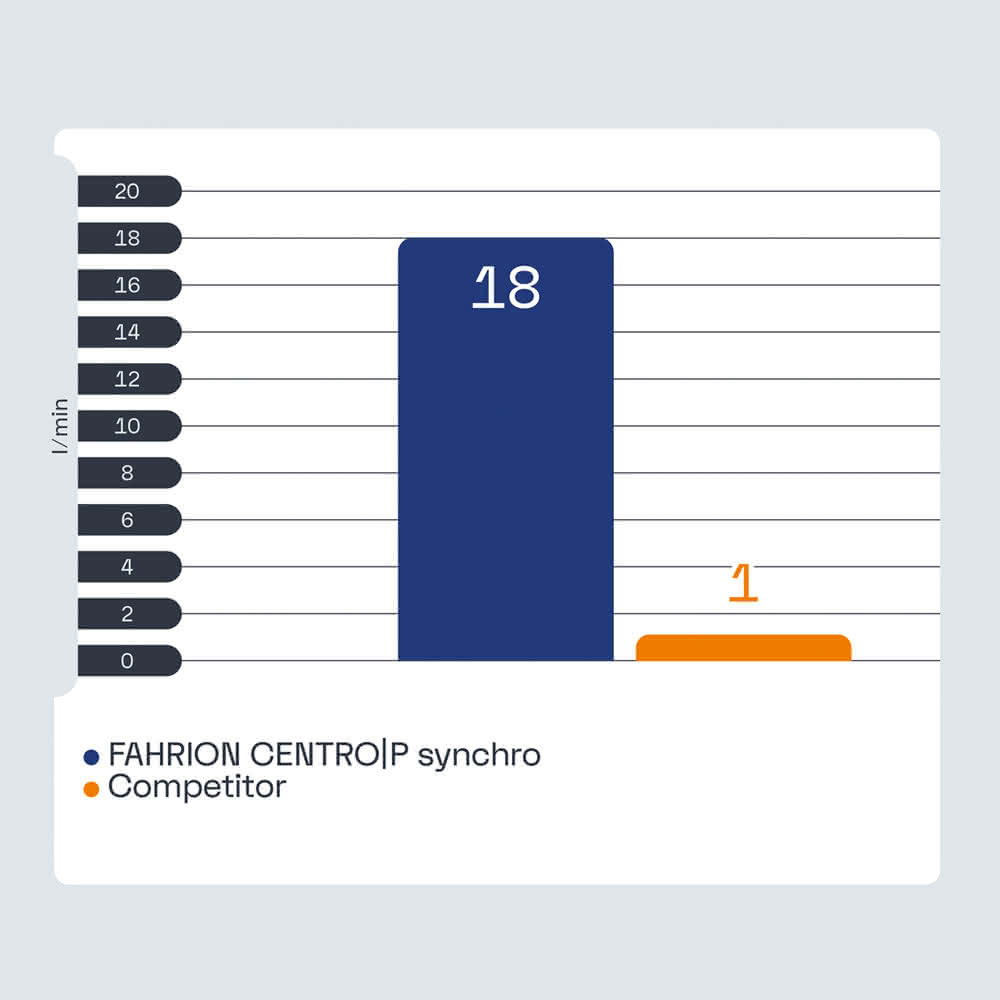

The more coolant that reaches the right place, the better the process

With a synchro chuck, the coolant cannot simply be fed through as with a standard chuck but must inevitably flow through several parts. This results in significant differences in the flow rates.

The optimised arrangement and the large cross-section of the channels in our

The synchro chucks from FAHRION achieve the highest flow rate of comparable chucks available on the market.

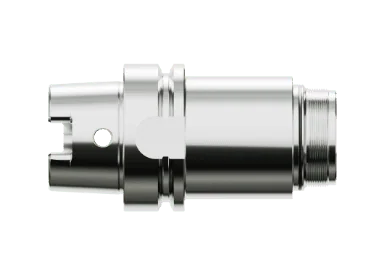

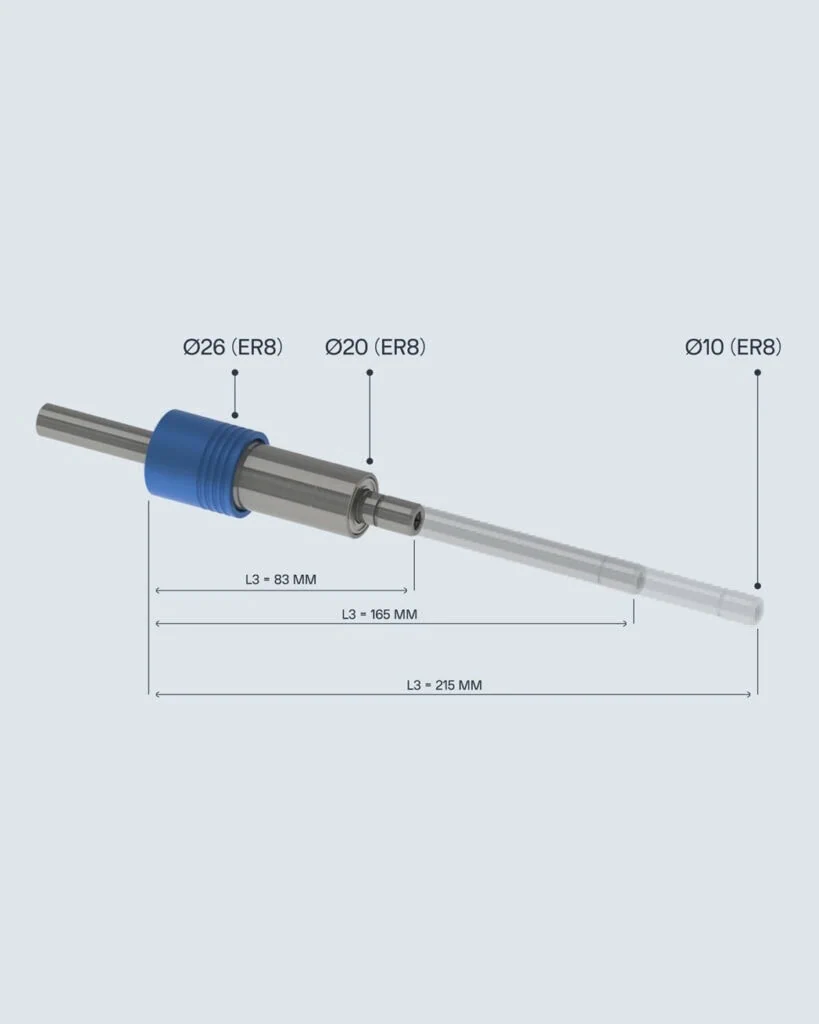

Additional highlight – precise and synchronised to the very end

The previously mentioned FAHRION-specific guide design ensures high concentricity even with long overhangs, right down to the smallest detail.

The Rubber-Flex-Clutch (RFC) provides the necessary damping properties in the axial and radial directions.

With a diameter of 10 mm, our Mini Synchro Chuck MSC8 is currently the slimmest system on the market (including the long-established FAHRION CENTRO|P technology).

It is unique in that the extended CENTRO|P synchro versions, despite their extremely slim outer contour, feature internal coolant supply.

ADDITIONALLY, YOU CAN ACHIEVE SIGNIFICANT COST SAVINGS:

→ You only need one FAHRION CENTRO|P synchro chuck in the desired extended version and a more affordable standard-length thread tap.

This eliminates the need for expensive long thread taps or corresponding thread cutting extensions.

The current product range can be found in our sales brochure ↗︎.

Lubrication is very important in threading

Generally, lubrication in machining serves to minimise friction, extend tool life, improve surface finish, reduce workpiece deformation and ensure process stability.

This is a key factor in ensuring efficient and precise metal cutting. Cooling lubricant (CL) reduces friction in machining, which is particularly crucial in threading, as this type of machining generates significant frictional forces.

In addition, the removal of chips by the cooling lubricant is absolutely essential in blind hole threads.

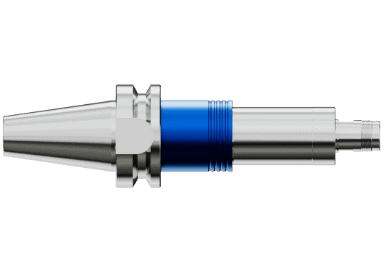

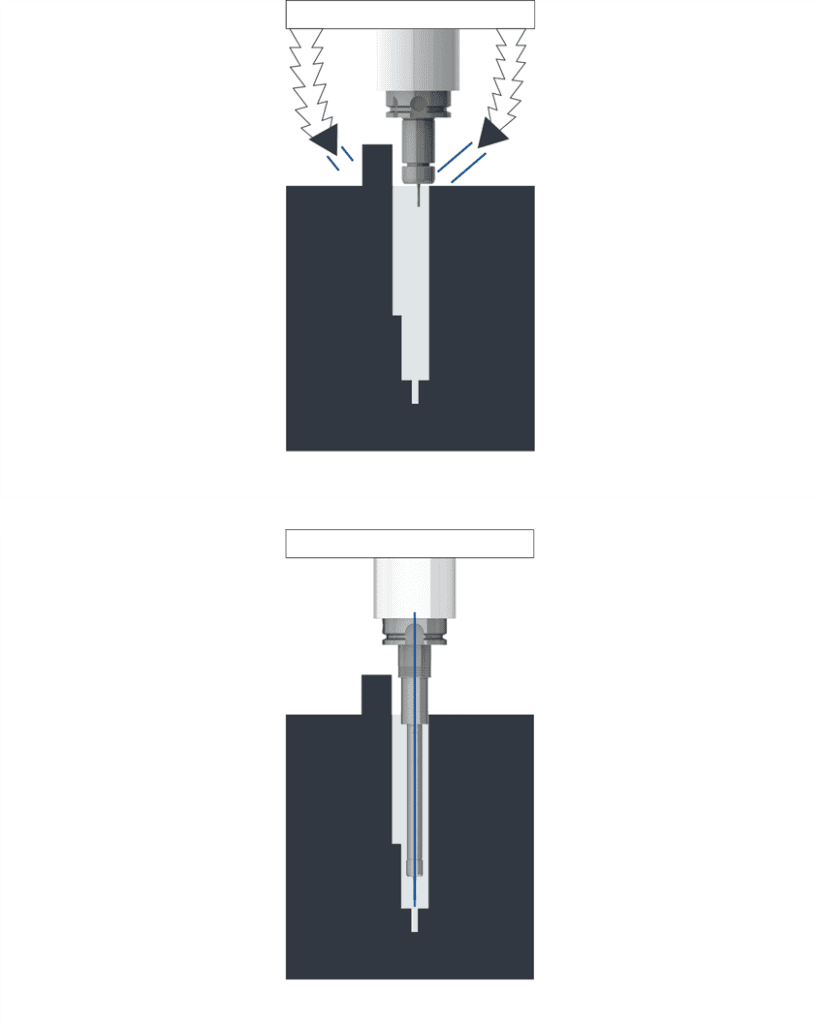

Advantages of internal lubrication

It is crucial that the coolant reaches the cutting edge in sufficient quantities and at adequate pressure.

For many operations, it is advantageous for the coolant to be fed through the tool.

As illustrated in the diagrams (Top image: External coolant supply/Bottom image: Internal coolant supply), internal coolant ensures that sufficient coolant always reaches the cutting edge, even in complex contours, rather than being wasted.

If internal coolant supply is possible through the chuck body, the exit can occur either through the tool or through the collet.